Levison Enterprises Preserves the Lost Art of Through Hole

Are you hitting a dead end trying to get your through hole board replaced or fixed?

Many electronic manufactures don’t do it anymore.

Though the benefits of surface mount assembly may have largely displaced through hole assembly, there are many applications where through hole assembly could remain the best choice.

At Levison Enterprises, we understand that it’s just not cost effective for our customers to eliminate through hole technology from our services. If you are looking for a team with experience and the technical skill to complete your through hole design, repair, or replacement, look no further than Levison Enterprises.

What Is Through Hole Assembly?

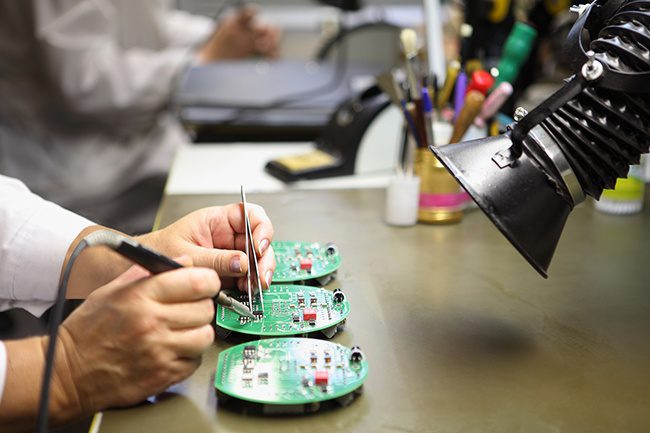

If you missed the simplicity of the through hole assembly, it’s when small holes are drilled into the circuit board and leads are threaded through to the opposite side.

The leads are then soldered into place, either by hand or using a wave-soldering machine, completing the assembly.

Comparison with Surface Mount Assembly

When it became difficult to manage the large numbers of pins that needed to be fit in integrated circuits, surface mount assembly answered the issue.

Because of the holes needing to be drilled with through hole assembly, through hole assembly simply was not able to accommodate the increasing number of components and the requirements for more holes to be drilled into the board. Another advantage of surface mounting? It’s faster and more affordable than through hole assembly.

Why Consider Through Hole Assembly?

If surface mount assembly has such advantages over through hole, why even consider it?

Legacy

While surface mounted assembly provides many modern advantages, most legacy systems have boards that were assembled using the through hole method.

If the project is based on an older design or you are replacing older boards, redesigning the entire board to accommodate a surface mount assembly doesn’t make much sense.

In these situations, it’s more cost-effective to replace the older board with another using the through hole assembly method.

Prototype

Prototyping is another area where through hole assembly often makes sense economically.

Because the components may be replaced in a through hole design, switching out components is often much simpler.

Due to the low numbers of boards that need to be produced during this phase of the project, the through hole assembly can also be cost effective.

Military and Aerospace

Not all these issues are about saving money.

Certain applications require greater durability for extreme conditions.

Military and aerospace especially present challenges in the form of extreme temperatures or mechanical stress on the board.

For these applications, the through hole assembly is usually the preferred choice for a project because it provides a stronger bond than surface mounted assembly is capable of.

Some through hole assemblies can withstand higher power demands than can be sustained with most surface mounted assembled boards.

Repair vs Replace

If reliability and longevity are a large concern on a project, the through hole assembled board is the better candidate to withstand the test of time.

Through hole systems are built for the long haul – that’s why there are still systems around to repair!

Companies leverage legacy technology because they are an investment and will be around long enough to be fixed rather than replaced – and that’s the wisest way to be cost-efficient.

Through Hole Expertise for Any Project

Levison Enterprises has been providing high-quality through hole assembly for years for our clients.

We have extensively trained staff who are expert technicians in hand soldering and can tackle your project with precision and speed.

We manually hand solder and use a wave soldering machine for production of every through hole printed circuit board, depending on the needs of the project, client, or level of difficulty. Where most organizations avoid through hole assembly, Levison Enterprises has maintained the lost art of hand solder production. Precision matters.

With our team, the entire production staff at Levison Enterprises is IPC J Standard certified for soldering and inspecting up to IPC-A-610 standards.

Levison Enterprises has quality control measures in place to ensure our clients receive 100% satisfaction, 100% of the time. Our process can even meet lead-free industry standards for projects that require lead-free production.

If you are considering using through hole assembly for your project, talk to the Levison Enterprises team.

Our experts can provide the information you need to make a better-informed choice, and our in-house engineers can provide recommendations on your design to make production faster and more efficient.