5 Key Qualities to Look for in an Electronic Manufacturer

So, you are beginning your search for a new electronic manufacturer.

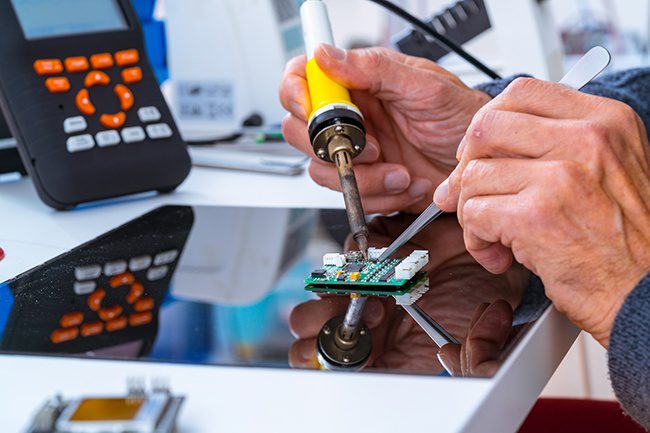

On the surface, many electronic manufacturing service companies appear very similar. They will have a roster of the capabilities, coupled with some images of printed circuit boards, cable assemblies, and processing equipment. Perhaps you are a seasoned professional and have been through this process a couple times before. For others, this might be their first rodeo. Either way, here are some key factors that you should look for to be sure you are evaluating the key qualities and attributes that will be the deciding factors between your project being a success or a stepping stone on your next search for another electronics manufacturing partner.

Proficiency and a Proven Track Record

When you begin talking to electronic contract manufacturers, you will likely be given a sales pitch about what they can do to outshine their competitors.

How can you be certain they can live up to all these promises?

It is paramount that you confirm they possess the expertise to handle the needs of your project from start to finish. Do your research and see how their capabilities and processes align with your project goals. If they lack up to date equipment or engineering experience, there’s a greater chance that your projects will fall short of expectations or will take longer than anticipated.

Choosing an electronics manufacturing service provider that has design and manufacturing under one roof will help ensure that your project is completed on time and within your budget. Don’t be afraid to ask for references for some of their clients that they have performed similar work to your project for.

While it is unlikely they will connect you with someone that had a poor experience, you’d be surprised how much you can learn from a direct call to a former or current customer with a project similar to yours.

Robust Quality Assurance Measures

Quality assurance processes throughout every step of the production process are essential to minimize the risk of production errors, use of non-conforming parts, and product malfunction.

A partner with industry recognized quality certifications shows that they conduct their due diligence in sourcing, testing, and assuring quality throughout every stage.

Their processes are also documented, which can insulate you from liability should an issue ever arise. Look for a quality certified contractor that has its own robust processes for production, testing, inspection, and even shipping and distribution.

In-House Engineering and Design

An electronic contract manufacturer that has an experienced in-house design and engineering team has a big advantage over those that do not. These teams serve a valuable purpose, as they help your company identify any potential issues with your product and make suggestions that can make your production process run smoothly.

With superior attention to detail, an in-house team can consider every aspect of your product’s design and recommend test strategies that aid in quality assurance.

These teams help guide your product through its entire development process, not just the initial stages.

Customer Communication

Good communication with your electronic contract manufacturer is paramount. This helps avoid any delays in production and delivery. It’s essential to have a transparent relationship with your manufacturing partner.

Pay close attention to the level of detail they go into about their processes and the amount of communication that will take place before, during, and after your project.

Those that provide a higher level of detail are showcasing their experience and confirming they have established and follow a specific process will ensure your project is handled with white gloves.

Vague or very high-level explanations of the various stages of your project should throw up some red flags.

Timely Delivery

Be sure that you understand not only the abilities of the electronics manufacturer you choose, but also understand their capacity.

Too often, projects are taken on that stretch the limits of their capacity and leave little room for error in the timeline.

This makes operating in a “perfect world” scenario the only avenue to delivering your project on time.

While we all like to think we operate without hiccups, we all know that is not always the case.

Follow These Key Qualities to Making the Right Choice

The right electronic contract manufacturer can make all the difference in your product’s quality, cost, and delivery. When you choose Levison as your partner, we streamline the process and make it easier to innovate and create. We employ robust quality assurance mechanisms at every level and work to make your product the best it can be.

We make switching to a new electronics manufacturing service easy and will handle all the legwork while keeping you informed every step of the way.

Transparency, quality, and an in-house team of designers and engineers – that’s the Levison difference.

Contact us today for a free estimate on your next project assembly.