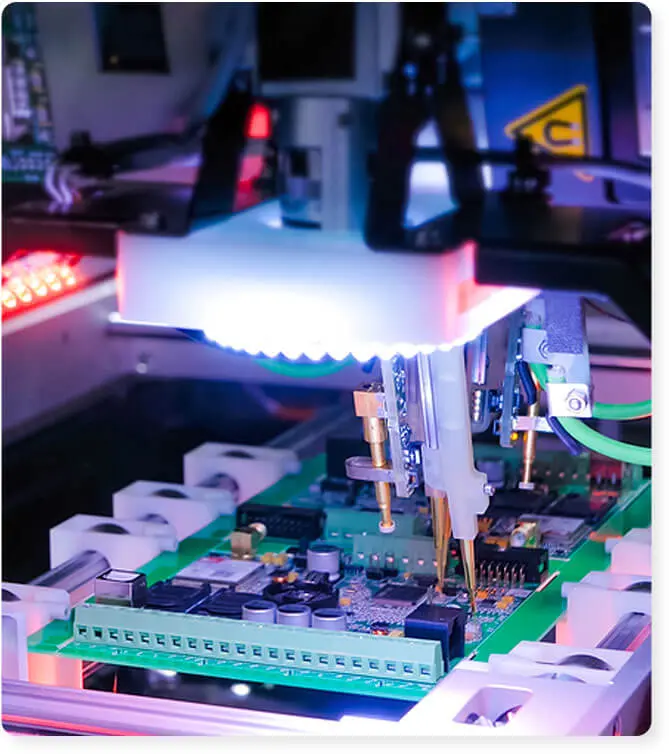

Electronic Assembly Services

Levison Enterprises believes that a strong foundation in electronic manufacturing quality control leads to high-quality products. Our AS9100 and ISO 9001 certifications by NSF-ISR are evidence that we hold ourselves to the highest standards in the industry. As an ISO 13485 Certified by NSF-ISR FDA Registered medical device manufacturer, we are excited about the possibilities that new groundbreaking technologies will bring to our healthcare.

As a CMMC Level 3 facility, Levison Enterprises has the processes in place and are confident in our ability to be ready for any mission-ready projects.

Case Studies

At Levison Enterprises, we have invested time and resources into obtaining and maintaining our quality certifications. We have adopted stringent process systems throughout our entire design and manufacturing operations. Each member of the Levison Enterprises team takes pride in knowing they have played a part in our process metrics. Through a culture of continuous improvement, we conduct internal and external reviews and audits. We believe that a strong focus on reliability leads to customer satisfaction.

AS9100 | ISO 9001 | ISO 13485 CERTIFIED by NSF-ISR

ITAR REGISTERED

IPC AND J STANDARD CERTIFIED

CMMC LEVEL 3

FDA REGISTERED

8 Key Things to Know Before

Hiring an Electronic Contract Manufacturer

The process of hiring a new ECM is never an easy task. We’ve outlined 8 key areas that you should know when vetting your next electronic assembly partner to ensure that you are making the right choice.