What Comes First in Your PCB Development

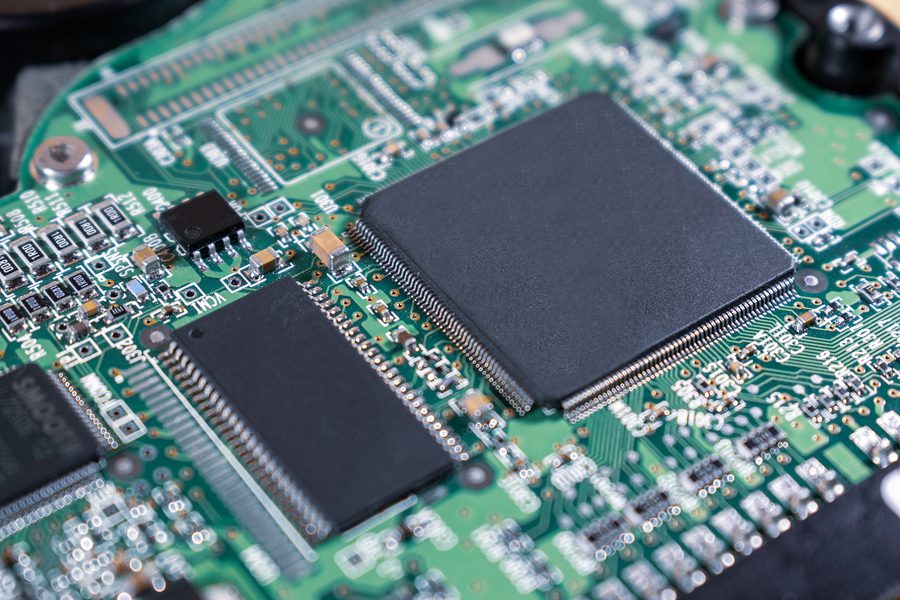

As you develop your printed circuit board, it is important to know the way PCB manufacturing works. You can waste a lot of time and run into trouble early in your PCB development process without a clear view of the PCB manufacturing industry. There is a lot of labor and machining that go together to take your board from design to a fully fabricated product.

However, a simple slip can cause your project to come crashing down. You don’t want a disconnect to occur between your design and finished product. That is why understanding the process of PCB development and manufacturing can help you avoid unnecessary and costly errors.

Differences Between PCB Manufacturing and PCB Assembly

A lot of people confuse PCB manufacturing and PCB assembly. It’s an easy mistake to make. Sometimes it’s just a slip of the tongue. But the difference between the two is what can lead to your PCB project’s ultimate failure or success.

PCB manufacturing refers to starting from scratch. It begins with a bare board and a design. The most commonly used digital format used for PCB design is a Gerber file. The file is submitted to a manufacturer. When manufacturing begins, an insulating material is put down first, then copper is applied in layers, as well as well as other preparations that include plating and drilling.

This is where PCB assembly begins. It cannot start until the manufacturing of the bare board is complete. During the assembly phase, various technologies are used to place components on the board in order to make it function properly.

Getting a DFM

Getting a Design for Manufacturability (DFM) analysis is an extremely important step in PCB development. The decisions you make following your DFM will determine how well your PCB will be made and how well it will perform. A DFM early in the design stage will determine if your design will withstand the manufacturing process and successful boards can be produced. It should catch any potential calculation errors and design flaws that could end up as costly mistakes down the road. It will also determine if it is possible to reduce the cost by swapping parts, streamlining the design, and/or using different technologies for assembly.

In addition, it will save time by catching mistakes early on when they can be corrected more easily. Overall, a successfully executed DFM will speed up production, reduce costs, and add to the quality of your completed project.

Through-Hole or SMT: Which is Better For You?

Another early decision in PCB development is determining which technology will be used to build your board. The components you are using and the function of your board will help you decide if surface mount technology (SMT) or through-hole technology should be used.

SMT is better for smaller PCB sizes and higher-density components. It’s done by mounting components directly on the surface of the board. It’s cheaper and requires less time, but makes components more prone to mechanical stress.

Through-hole technology requires holes to be drilled into a board and then PCB components are inserted into them. They are then soldered into place. It can be time consuming, and therefore more costly. However, through-hole results in a stronger mechanical bond that can withstand greater stress.

Testing In-House

Testing should be done early and often during PCB development. It begins in the design stage when your prototype will be tested for functionality. Testing will continue throughout the manufacturing and assembly stages for quality assurance. Before anything is shipped, your PCB will also be put through its paces and tested to ensure it meets or exceeds specifications for usage by targeted industries. Having an ECM with in-house testing will speed up the process. Necessary adjustments will be able to be made on site and in a timely manner.

You want an ECM who can do this and much more. A PCB manufacturing partner should be someone you can rely on and has your best interests in mind. Levison Enterprises is the company. With more than 100 years of combined experience, Levison is committed to quality you can count on. If you’re ready to move forward with your PCB development, contact Levison today.