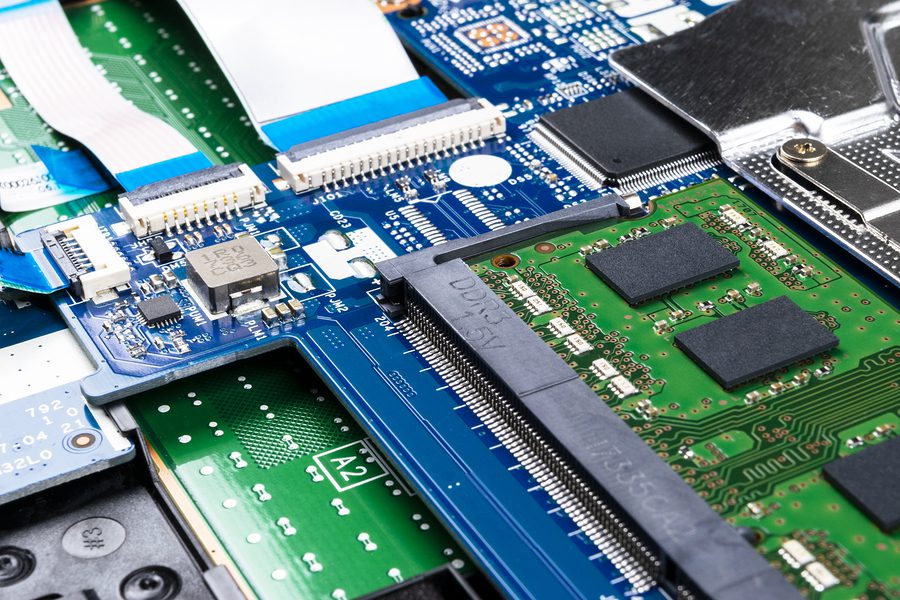

PCB Component Factors That Are Driving Up Your Electronic Assembly Quote

The cost of electronic assembly can vary as much as the design of a printed circuit board (PCB.) Most think the cost is driven by the availably of the multitude of components needed for PCB assembly. While that may be an influence, there are a whole host of other factors that comes into play too. Add them all together and your costs can skyrocket. Component shortages are real, but here are some other factors that may be driving up the cost of your PCB.

Components and Other Considerations

When it comes to components, there are multiple considerations that affect the cost of your electronic assembly. First and foremost is the number of components used. The more parts you use, obviously, the more it will cost to purchase your supplies. This includes the size of the components and the number of placements required. Costs go up as the number of placements your PCB assembly requires. So, a board packed with tiny components can cost you big.

Other pricing factors include parts availability. It is a simple case of supply and demand. Components that hard to get and/or are in high demand cost more.

The technology used for assembly will affect cost, too. Surface Mount Technology is generally less expensive. However, Through Hole Technology is extremely reliable. Some assemblies may require both of these technologies to be used. This almost always requires some hand assembly at the end, which also adds a lot to the cost. And, as expected, a single sided board assembly will cost a lot less than building big, multi-layer boards.

Special processes required of your electronic assembly will quickly add up, as well. Hand soldering, wave solder, and coating can add to your tab.

Ways to Keep PCB Costs Down

The good news is there are some tried and true ways to reduce the cost of your electronic assembly.

Use an ECM with Vendor Relationships

To battle the issue of component costs, use an ECM with existing vendor relationships. Not only will this allow you to source hard to find parts, it will get you a good price for them. In addition, your ECM’s trusted network of suppliers will provide you with quality components and reduce the risk of counterfeit or faulty parts being used in your build.

Complete BOM

Another way to reduce the price tag of your PCB is to take the time to complete a Bill of Materials (BOM.) This is a list of all of the items that will need to be purchased and inventoried to make your circuit board. An accurate BOM provides details on all the parts required to build a shippable product. Leaving components off of the bill of materials is a major pitfall that can mess up PCB pricing.

Getting a DFM

A Design for Manufacturing (DFM) assessment can be a real money saver when it comes to your electronic assembly. The DFM will determine if your design meets the requirements of manufacturing processes to actually produce the PCB. The analysis will check areas including complexity, materials to be used, components, number of layers, number and sizes of holes, and the type of tech being used. The results of your DFM will allow you and your manufacturing partner to look at your design and see where it can be adapted to streamline cost.

Working with the right ECM for your board assembly can mean a big difference to your budget. Levison Enterprises works with each customer to ensure they get the PCBs they need, the way they need them, and at the best possible price. Contact Levison today to see how we can get you the electronic assembly you need on time and on budget.