What is IPC-A-610 J-STD-001 For An Electronic Manufacturer

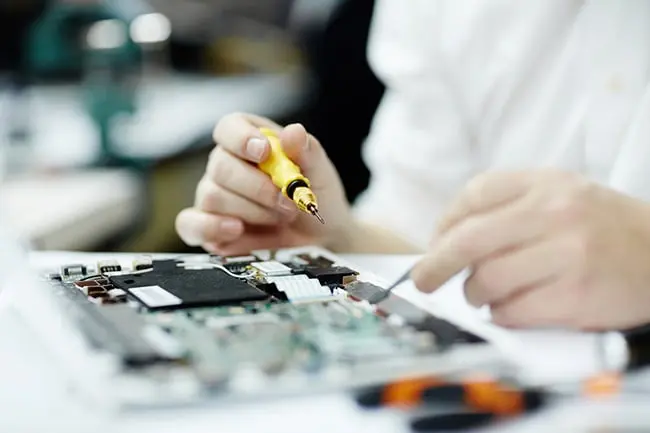

J Standard, or it’s more official title IPC J-STD-001 is a standard that lists the requirements for the manufacture of electronic assemblies. This standard is published by the IPC as “Requirements for Soldered Electrical and Electronic Assemblies” and includes guidance on materials, manufacturing methods, and verification criteria for an electronic manufacturer.

This standard especially emphasizes process control and provides an industry-level standard for a broad range of electronic products.

What is the Difference Between J Standard and IPC-A-610?

J Standard is kin to another high-level IPC certification, IPC-A-610. Where IPC-A-610 is concerned with the inspection of the final product, J Standard covers the process of building the product and the environment in which it is built. Factors include everything from lighting to temperature. J Standard speaks to plated through hole soldering, surface mount soldering, conformal coating, and inspection of the solder joint.

IPC-A-610 includes all of J Standard, plus other issues specifically related to the final assembly and not covered by the soldering standards. IPC-A-610 also details the level of acceptability in the final product.

What is Required to Follow to J Standard?

Electronic Manufacturer Certification can be obtained by individual assembly process engineers, assembly technicians quality assurance supervisors, training managers and other similar positions that maintain responsibility for the quality of soldered electronic assemblies.

To be certified, an individual attends training at an IPC-authorized J-STD training. Soldering labs and instruction prepare the individual for a certification examination. Topics of focus include wires and terminals, through hole technology, surface mount technology, and inspection, given the high-level of quality demanded by this standard. Re-certification must be completed every two years.

J Standard at Levison Enterprises

At Levison Enterprises we fully understand that the IPC J-STD-001 Requirements for Soldered Electrical and Electronic Assemblies has emerged as the preeminent standard for electronics assembly manufacturing worldwide. In order to demonstrate our commitment to our customer needs and to enable us in meeting or exceeding the quality expectations of our customers, Levison Enterprises has incorporated a comprehensive, knowledge-based Training and Certification Program that is highly recognized throughout the electronics industry to our training requirements.

All of our electronic manufacturing assemblers receive intensive training to the methods and procedures presented in the J-STD-001 document from an IPC-approved certification instructor that provides them with the valuable credentials needed to further recognize their understanding of the J-STD-001.

Our comprehensive Training and Certification Program is designed to ensure our assemblers recognize, understand and comply with the following J-STD-001 requirements:

- General requirements, such as safety, tools, and electrostatic discharge (ESD)

- Wire and terminal assembly requirements

- Through-hole technology requirements

- Surface mount technology requirements

- General soldered connection acceptance requirements (including Lead-Free)

- Machine and reflow soldering process requirements

- Test methods and related standards

- Using statistical process control methodology

Our partners can be assured that all assembly performed at Levison Enterprises is of the highest quality and reliability. Levison Enterprises has distinguished itself by being a valued, collaborative electronic manufacturer and partner to our customers. Our years of electronics experience enable Levison Enterprises to tackle even the most challenging projects while meeting or exceeding the quality, schedule, and cost expectations of our customers.

Contact Levison Enterprises to see how our experience and commitment to quality can enhance your project, assembly, and overall electronic contract manufacturing experience.