Does Your ECM Have the Technical Knowhow to Handle Your Project?

You’re looking for an ECM with the ability to take your project from idea to consumer’s hands. How do you know if an ECM will provide quality work on time? After all, your project’s success depends on it. An ECM with sub-par technical chops opens you up to defective and generally poor-quality products. You need an electronic contract manufacturer that can do it all – a turnkey PCB assembly. So, what sets a turnkey operation above the rest?

Quality Characteristics

A qualified ECM will have certain characteristics that are indicators of their standard of quality. The company will have strictly followed processes for design and manufacturing to obtain and maintain quality. Look for a manufacturing partner that conducts various internal and external reviews and audits. An ECM with a program of continuous improvement will provide on time delivery and top-quality products while controlling costs. This is the kind of company you can trust with your printed circuit board assembly.

Industry Certifications

Putting a vast amount of time and resources into obtaining and maintaining industry quality certifications is a clear sign an ECM can handle your PCB project. The certifications a company has earned tells you its technical capabilities. Certifications to look for include:

· ISO 9001 – The most widely recognized quality certification that demonstrates statutory and regulatory requirements and customer satisfaction.

· NIST SP800-171 – Requirements that any non-Federal computer system must follow in order to store and process Controlled Unclassified Information (CUI).

· AS9100 – An aerospace quality management system considered a “highly stringent” quality standard.

· ITAR (International Traffic in Arms Regulations) – This certification from the United States Department of State controls import and export of sensitive defense-related materials and information.

· IPC and J Standards – These are electronics workmanship certifications for soldering cables and circuit board assemblies.

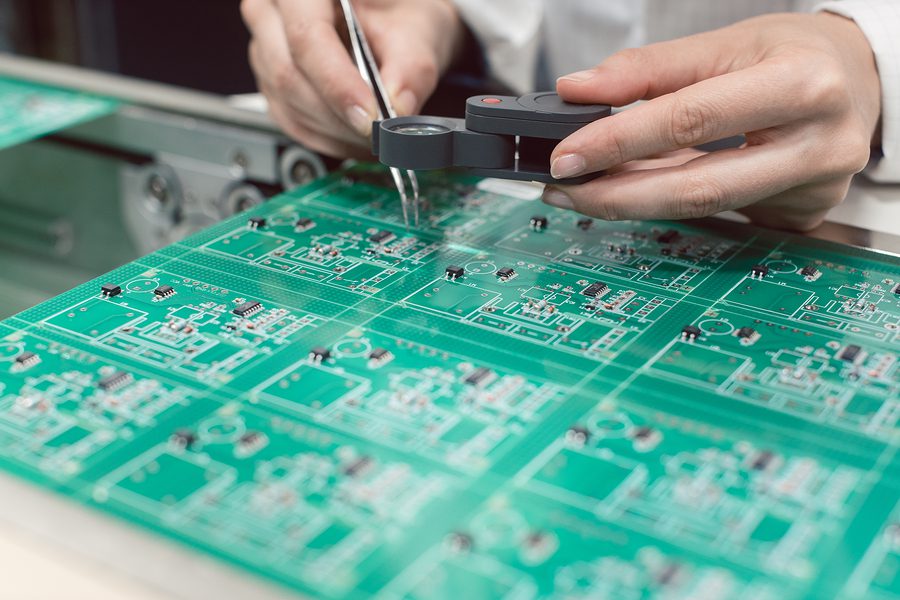

On-Site Engineering Support

An ECM is nothing without dedicated engineering support. A company that employs in-house engineers will definitely be able to successfully handle your turnkey PCB assembly. On-site engineers will oversee each stage of the manufacturing process. They will be on hand to detect potential problems and solve them before they snowball and either stall production or leave you with an inferior product.

Working with a Single ECM

Working with a single electronic contract manufacturer for turnkey PCB assembly will greatly impact your quality, flexibility, and cost. Sticking with a single ECM means you don’t have to waste time coordinating with different people at different locations. It will also save you on shipping costs. Plus, your ECM’s technicians will know your build from start to finish.

Consider consolidating your entire electronic and printed circuit board assembly with Levison Enterprises. We have a full range of capabilities and experience, and the industry certifications we have earned proves we have the high standards and technical know-how to handle your project. Contact us today to find out how the Levison advantage can work for you.