Are You Leveraging Your ECM’s Capabilities?

In today’s competitive landscape, ECMs (Electronic Contract Manufacturers) need to do more than just fill orders that meet product specifications. Top ECMs work with their OEM partners to ensure everyone is on the same page with the goal of producing the best outcomes, from the engineers and designers to materials and components.

Opportunities for improving a final product exist, but it requires a unique approach and a Design for Manufacturing (DFM). OEMs that choose to partner with an ECM experienced in Design for Manufacturing have opportunities to improve production and logistics that save time and money in the long run. Applying a DFM approach reduces the number of required areas of manufacturing focus to improve the final product quality. This results in consistent, reliable products that get to market faster and OEMs benefit from that competitive edge.

DFM

Proper DFM analysis requires component design, thorough testing, and access to the latest prototyping technologies and analytical tools. The end goal of a DFM analysis is to find a product design involving the least complexity in the manufacturing of different components. Modern electronics are complex, so a DFM analysis can help find solutions to trimming excess material and producing more streamlined products. While Design for Assembly aims to cut production and assembly costs, DFM analysis aims to reduce the overall costs for producing all parts of a product or assembly.

Prototyping

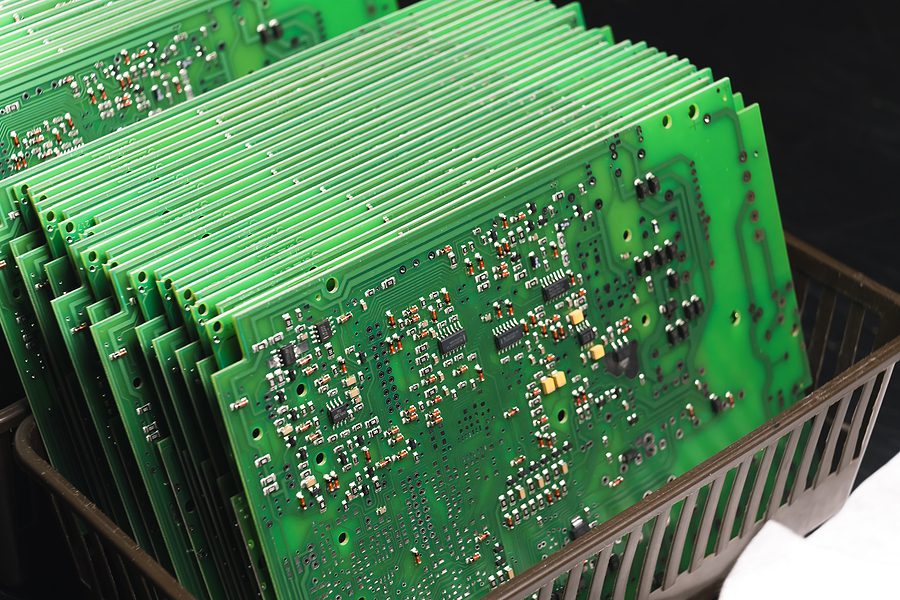

Pre-production work, like printed circuit board (PCB) prototyping, is crucial in building a cost-efficient high-quality product. PCBs are intricate and will perform critical duties in your project. Prototyping your PCB is always recommended no matter the industry. There are several benefits of outsourcing to an ECM partner with 3D printing capabilities. It allows for rapid prototyping to ensure your design is correct during pre-production and also during the PCB prototype production phase.

Low Volume Runs

PCB assembly can begin with prototyping to allow for limited or low volume runs to ensure functionality before a full run. You need an ECM with cutting edge infrastructure and specialized components necessary to build parts and products to the exact specifications required, or rather a partner who incorporates traditional and modernized technologies to meet your specific needs.

Design Services

Having an ECM partner who offers a complete lineup of design services from a team of in-house engineers provides a quick turnaround for time-sensitive projects without sacrificing quality. This allows streamlined designs even for the most complicated projects. Designs can then be incorporated into high-speed multi-layer boards. The right engineers are experienced in CAD modeling and a variety of industries including medical, defense, food safety, aerospace, and government projects. DFM analysis is crucial for delivering the most cost-effective, streamlined, efficient design, so you need engineers who understand how to incorporate DFM into your PCB design for the highest quality level.

Engineering Services

Having in-house engineers is vital for PCB design and manufacturing. An extra set of eyes on your printed circuit board can streamline the design process and improve your ideas. In-house engineers remain on site from the onset to help in mechanical design, electronic design, and software design. Having the right engineering services on your side means they can tackle the most complicated and difficult design projects and applications. They will also examine your existing design and make suggestions to increase the reliability, efficiency, cost-effectiveness, and manufacturability to optimize your production process. Finally, having an experienced engineer onsite working on your PCB board design from the beginning minimizes the need for troubleshooting or repairs later down the line.

More Than Manufacturing

Understanding what to look for when evaluating potential ECM partners will not only connect you with experienced suppliers but you’ll gain several pivotal benefits that will save you time and money on your projects. Partnering with an ECM who can assist you during the design phase of your project can help you avoid manufacturing delays due to design errors and get your product to market faster.

Start Your Quote Now!When you find the right turnkey ECM partner with engineers on site, multi-industry experience, and design services, you possess everything you need to ensure your product is designed in the best, most efficient way in terms of ease of manufacturing.

Levison Enterprises offers design support with turnkey manufacturing. If you partner with us, we will ensure your product is designed for manufacturing, saving you costly errors that could delay your project. We will transform your project from a conceptual idea to a quality finished product. For a turnkey shop containing vast industry knowledge and capabilities to help you create the best design possible while staying on budget and keeping timelines in check, contact Levison Enterprises for a quote today.