7 Things to Look for in a PCB Manufacturing Partner

Deciding to outsource your PCB manufacturing isn’t always a difficult decision, but finding the right PCB manufacturing partner can be. Many potential partners will make promises, but there are big differences when it comes to quality, customer service, and capabilities.

1. Turnkey Service

A turnkey manufacturer will fabricate and assemble your PCBs, as well as procure and manage your components. You will work to develop a design that works for you, but your PCB manufacturing partner will do everything else to provide you with a fully-built, ready-to-ship PCB. In many cases, a turnkey service can even deliver the finished components directly to your clients.

2. Multi-Industry Experience

Consider how long your PCB manufacturing partner has been in business, and how that experience is relevant to different industries. Multi-industry experience shows that a partner is committed to a thorough understanding of PCBs and their applications. A partner with many years of experience will have honed their process to guarantee you quality service. An experienced partner will understand all the ins and outs of PCBs and will make sure that they are able to meet your deadline and provide a quality product.

3. Engineers On-Site

Having on-site engineers is a crucial part of finding a quality PCB manufacturing partner. On-site engineers will be there throughout the process for any potential tweaks and adjustments your design may need. If testing or prototyping merits a change, having the engineering team present will save you both time and money.

4. Certifications Relevant to Your Field and Product

When looking for a PCB manufacturing partner, it’s important to determine if your potential partner is adequately certified. If the certifications you need aren’t there, you may find that they are not compliant to the local and state laws and regulations, which will cost you much more later on. Understand the certifications necessary for your build, and make sure the PCB manufacturing partner you choose has everything you need.

5. Reliable Communication

It is important that communication between you and your PCB manufacturing partner is strong. A quality partner should provide you with a project manager who will be the point person you can reach out to throughout the process. If possible, speak with other companies who have partnered with this particular PCB manufacturer. How was communication throughout the process?

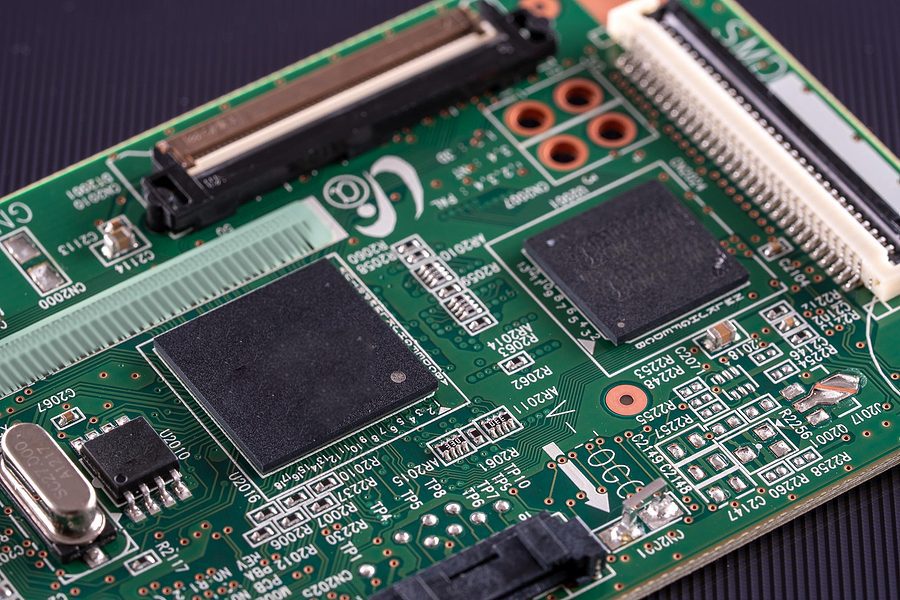

6. State of the Art Equipment

State of the art equipment demonstrates that a potential PCB manufacturing partner has a commitment to continued excellence and the upgrades necessary to both the equipment and education to make that happen. A partner who is using out-of-date equipment will likely not be able to complete your build to the quality you expect. When a partner has state of the art equipment, they have invested in themselves and believe in their value, and that indicates that you should too.

7. Capable of Building Your Product

Finally, ask the direct question and look for a direct answer. Is this PCB manufacturing partner capable of building your product? Consider similar builds they may have done for similar companies, and don’t be afraid to ask direct questions about their capabilities.

Start Your Quote Now!While it is important to consider the cost, remember that a quality manufacturer is well worth the investment. A cut rate PCB partner can lead to extended turnaround time, frustrations in communication, and products that don’t mean your company’s standards. When you are looking for a PCB manufacturing partner, ask the right questions to find the right partner for your project. We can help. With our extensive industry experience we are capable of building any PCB you need. Contact Levison Enterprises to learn more about our capabilities and get a free quote on your next project.