6 Budget Busters in PCB Assembly Quotes

PCB fabrication and assembly is a pretty straightforward process, however, there are factors early in the production process that could hold up your production and bust your budget before your printed circuit boards are even close to rolling off the assembly line. PCB designs and set ups can vary greatly, and so can the price to produce them.The good news is there are several elements of your PCB assembly that can be controlled early on to keep you within budget while maintaining the quality of your product.

Here are some tips on how to keep your PCB assembly quotes in line with your budget:

1. Number of Layers

Just because multilayer boards can include many layers doesn’t mean they should. Limiting layers can drop the price of your quote drastically, so it’s best to keep things simple and compact. Instead of adding another layer, consider making your board slightly larger to accommodate routing and power planes. As the number of layers increase, so does your cost.

2. Obsolete Parts

There is nothing that can kill your production timeline faster than obsolete parts and parts that have long lead times. This can send your PCB back to the drawing board for a redesign and waste valuable time as availability of alternative component materials is researched. This will not only hold up PCB assembly, but your quote as well. Your assembler will need to source parts and that could, in turn, drive up the price.

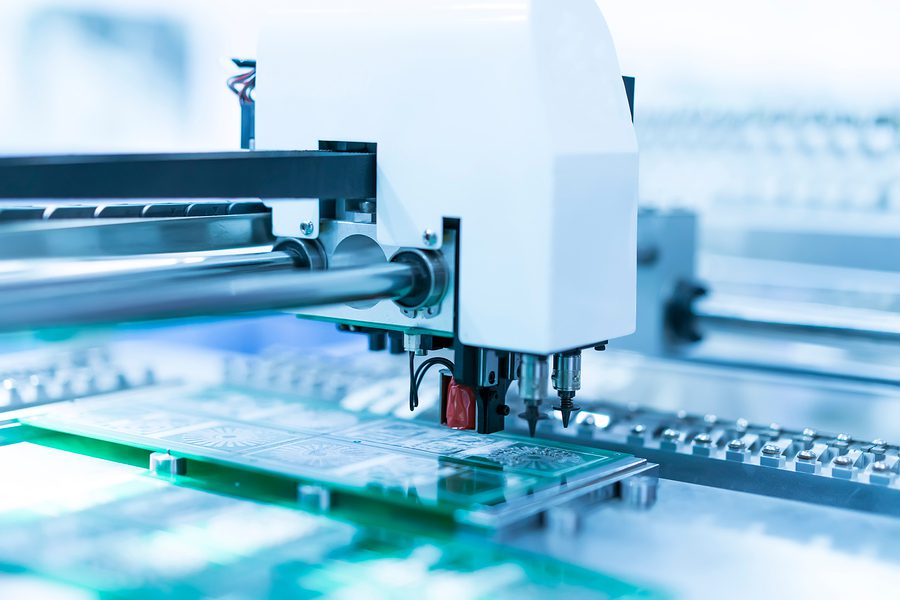

3. Complexity

Printed circuit boards can be very complex, but it’s best to keep them simple. Strategic design and engineering can save you money. Anything complex may require special equipment and handling for the assembly process. The more complicated your layout – the more you will be charged to manufacture it. In addition, make sure your PCB doesn’t require any unnecessary specifications. You may be charged extra for more stringent standards, so don’t ask for them if your PCB doesn’t need them.

4. Turn Around Time

Most PCB assemblers can turn around a job in a relatively short amount of time. However, a rush job will be reflected in your quote. The rule of thumb is the longer the lead time, the lower the price.

5. Packing Requirements

Packaging options are as diverse as PCBs themselves. It can range from tissue paper and bubble wrap to moisture barrier and vacuum sealing. You want packaging that will provide protection for your boards so they aren’t damaged in transit. The packaging will vary based on what you need to protect against, but you need to be aware that putting your PCBs into an enclosure that is custom or extremely intricate will cost you more money.

Email Sales6. Special Shipping/Handling Requirements

Your shipping costs will be determined by where your PCBs are being sent and how soon you need them to be there. Expedited shipping will drive up your shipping costs exponentially, and the location where your products will be delivered matters, too. Areas of the world considered “remote” by shipping companies can cost you extra time and money for guaranteed delivery. You also need to factor in customs tax fees if your PCBs are being shipped internationally, and those fees vary from country to country.

Hiccups like these can not only cost you more capital, but put your project behind schedule. In the world of electronics, time is certainly money. You want to be sure your project is thoroughly thought out and worked through before getting a quote for your PCB assembly. If you need help, talk to an ECM that has engineers on staff that will look over your PCB assembly and work with you to create exactly what you need, on time and on budget.

Let Levison Enterprises quote your project and build a better product for you. We can look over your PCB order to see where you can save money with maintaining the highest of quality standards. We want to be your electronic contract manufacturer. Contact Levison Enterprises today.