Your Guide to Quality Assurance in Medical Device Manufacturing

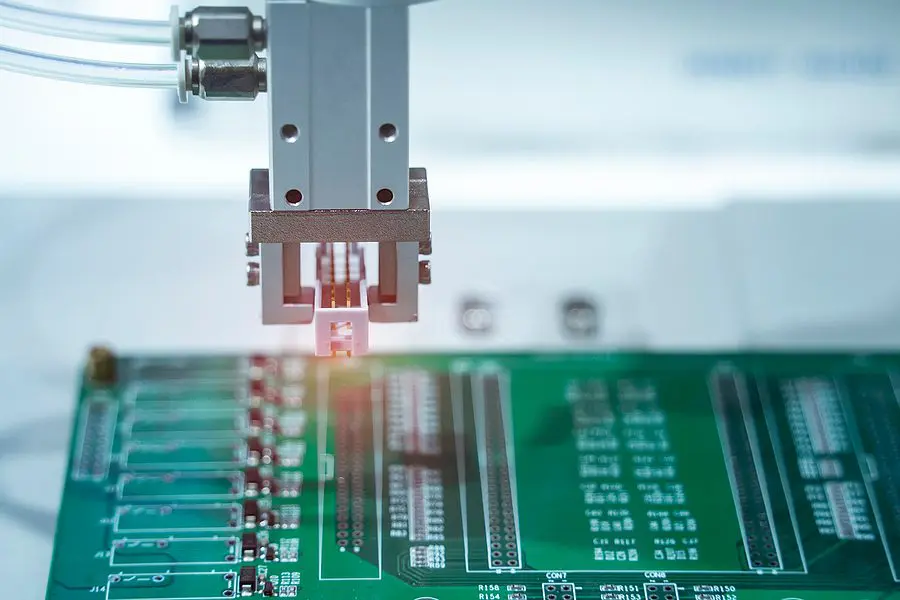

Avoiding problems and preventing mistakes, defects, and flaws in PCB manufacturing for medical devices is imperative. Quality assurance and quality control impact your end product. Undetected flaws during PCB manufacturing not only directly impact your boards, but could cause a dangerous malfunction for a device designed to save lives.

You need to know your medical devices are reliable. This is where quality assurance comes into play. Finding an ECM that goes the extra mile will help ensure consistency and safety during the medical device manufacturing process.

Extensive Medical Device Experience and Success

Not all electronic manufacturers understand all industries. You need to know your ECM can handle the requirements of medical device manufacturing. They must be aware of industry standards.

Make sure to check a potential manufacturing partner’s track record. Have they previously completed projects similar to yours?

An ECM with extensive medical industry experience and past success building PCBs for medical devices can be counted on to follow industry laws, regulations, guidelines, and specifications that will affect every stage of the manufacturing process.

Proper Certifications

Working with a manufacturer who has invested the time and effort to earn and maintain industry certifications ensures the electronics going into your medical device will meet or exceed industry standards. Your manufacturing partner should readily be able to provide you with its ISO and FDA compliance documentation, such as ISO 13485. Only certified ECMs will have the space, equipment, and expertise needed to produce high-quality electronics.

Turnkey

Most electronic medical device companies that use a turnkey solution experience a high level of reliability from their ECM partner. When you need help getting your medical device to production, a turnkey ECM can step in from the beginning, or at any point during the development process for that matter, and get it market ready.

You need to be guaranteed your device will perform satisfactorily for a specified period of time under the specified use conditions. To ensure this, your turnkey ECM will test your device repeatedly under various scenarios to ensure it will function properly when a patient needs it the most.

Counterfeit Parts Avoidance Process in Place

Counterfeit parts are a big problem in the electronic manufacturing industry. It is a risk medical device manufacturing needs to completely avoid. This can be done by working with an ECM that already has a great counterfeit avoidance process in place. The quality control plan will mitigate risk by ensuring part and product traceability. This makes it easy to determine what raw materials were used in the product, as well as how long, where, and under what conditions items were stored in the warehouse, as well as important documentation like specifications, certifications, and quality records.

Continuous Improvement Processes

Electronic manufacturers who use a continuous improvement process like Plan-Do-Check-Act are ahead of the quality assurance curve in medical device manufacturing. These processes identify opportunities that benefit their business without interfering with day-to-day operations. These advantages increase the value of their goods and services. Increased productivity, higher quality, and lower costs are all part of this.

Let Levison Work for You

Inferior product quality could put patients, your company, and your reputation at risk. Your best bet is to choose an ECM with these quality assurance processes already in place.

Levison Enterprises is a company you can count on for PCBs and medical device manufacturing. We have quality control systems already in place to ensure your product’s success.

We are AS9100, ISO 9001 certified, ISO 13485 certified, IPC and J Standard certified, and U.S. SBA certified, as well as ITAR registered. We have the experience and knowledge to help you with your next project.

Start Your Quote Now!Contact Levison Enterprises today to see how our team can work for you. Our turnkey service with multi-industry experience can help you develop and deliver a high-quality medical device.