You Need More Than a Standard Manufacturer

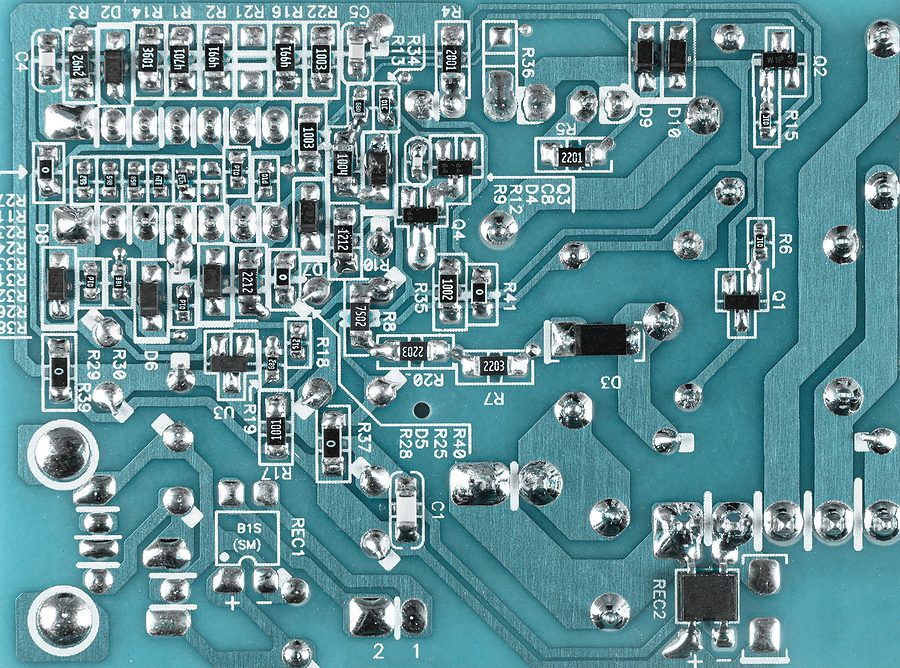

While many industries understand the need to outsource PCB manufacturing, they quickly find that not all manufacturers are created equal. Standard manufacturers can handle the actual assembly, but a turnkey manufacturer can do so much more than that. A turnkey electronic contract manufacturer (ECM) can handle every aspect of your PCB project, from design, through parts procurement, and even on to assembly and delivery. A turnkey ECM will take your project from the design stage through to completion without the need for additional outsourcing.

Full Service ECMs Serve All Your Design Needs

While your business has created the initial design, a full-service turnkey ECM can take your design and use their engineering team to optimize that design for production. Design-for-Manufacturability (DFM) analysis is available to streamline your plans and ensure that the design is optimized for efficient manufacturing.

On-Site Engineers Make the Project Run Smoothly

Having an on-site engineering team will make your project run smoothly through every stage. The engineers can develop a variety of prototypes that will allow both you and the engineering team to see the design and its capabilities before beginning a full production run. Engineers can also reverse engineer your product to optimize its design, which not only allows legacy products to remain relevant, but will assist with troubleshooting and potential errors.

Quality control is important, and on-site engineers available to do the testing throughout each stage of production can make a big difference. In-house engineers are there for any troubleshooting that may be necessary, detecting any potential problems early and addressing them quickly and efficiently, which ultimately saves you time and money. Having the on-site engineers available throughout the process – not just simply at the end – can mean the difference between a high quality end product and one that leaves much to be desired.

The Right Partner Has Vetted Suppliers and a Reliable Supply Chain

Choosing the right partner as your ECM needs means that you will have a team who can handle every aspect of the build without overextending your own in-house resources. Domestic ECMs can make sure that all the materials and components used in your project are not only the highest quality, but come from vetted suppliers that adhere to strict quality standards. Counterfeit parts can be a real issue, but a quality ECM, especially a domestic ECM, will have the inventory control in place and counterfeit parts mitigation processes to follow which drastically impacts any risk of counterfeit parts.

Advantages of a Turnkey Facility

Using a turnkey ECM can save you both time and money throughout the process. When your entire project is handled in one shop, you will not have the hassle of moving your product through different facilities, increasing the cost, time, and risk for error. A turnkey facility has the experts to see your project through with the facility, capabilities, and project management ready to handle every stage of your project.

You are the creative force behind your brand. When you partner with a reliable, experienced, and capable turnkey ECM, you can focus your own time and energy on growing your business, strengthening customer relations, and developing your next great product.

Start Your Quote Now!A domestic, turnkey ECM is the right choice for all of your PCBA needs. The right ECM will have the experience, expertise, and manufacturing ability to take your project through from design to delivery. A turnkey ECM can handle even the most complicated projects and meet all your needs. Whether you’re looking for a partner to help you develop and design your next product, or you just need a reliable, talented manufacturer to build and ship your product, we are here for you. Contact Levison Enterprises to discuss your next project today.