What Makes a Good Cable and Wire Harness Assembly Electronic Manufacturer?

Details matter when choosing the right cable and wire harness assembly manufacturer. The manufacturing equipment, the project team, and the capabilities the electronic manufacturer can provide all combine to make a successful product for your end user. A shop that doesn’t focus on the details can leave your design and assembly open to missteps.

Design

The most crucial step of any cable and wire harness assembly process is the planning and design. Anything involving wire harness manufacturing equipment needs to be thoroughly and precisely designed and planned out before any assembly begins. Engineers should take thorough measurements to know exactly how much wire is needed between every connection. Engineers will take these measurements and account for a bit of give in the connections as well so the connectors plug in easily without compromising the wire work.

Prototyping

Prototyping, or creating a test version of the final product, is very useful to work out any issues that weren’t addressed in the design phase. Prototyping allows engineers to work with the actual wire harness manufacturing equipment and move the process from the theoretical stage of the design to the experimental phase where the refinement happens. Often this stage will allow the engineers to come up with better designs and refined plans.

Capabilities Required

The ECM you partner with needs the right tools and capabilities for the project. So, how do you know if an ECM can take on your project? Ask them about previous projects they’ve successfully completed in your industry, or an industry similar to the complexity of yours. ECMs with a wide scope of capabilities across industries shows their commitment to excellence, so asking them about their overall industry capabilities will help you determine if they are a good match for your product. The right ECM partner will be eager to show you case studies.

The right equipment and expertise are necessary. Ask about certifications and how they meet quality standards. Certifications and quality standards are ways ECMs can prove their commitment to producing quality builds, and industry leaders tend to be very transparent with this information.

On-Site Engineers

As is made obvious by some of the other points that make a good cable and wire harness assembly manufacturer, having engineers on-site throughout the process is key. Some shops are not equipped to handle both the design and construction stages of the project, and therefore can’t see the project through from start to finish. This is often the case if they do not have a dedicated team of on-site engineers. Turnkey services will save time and money. The ability to troubleshoot on the fly will keep your timeline on track.

Final Assembly

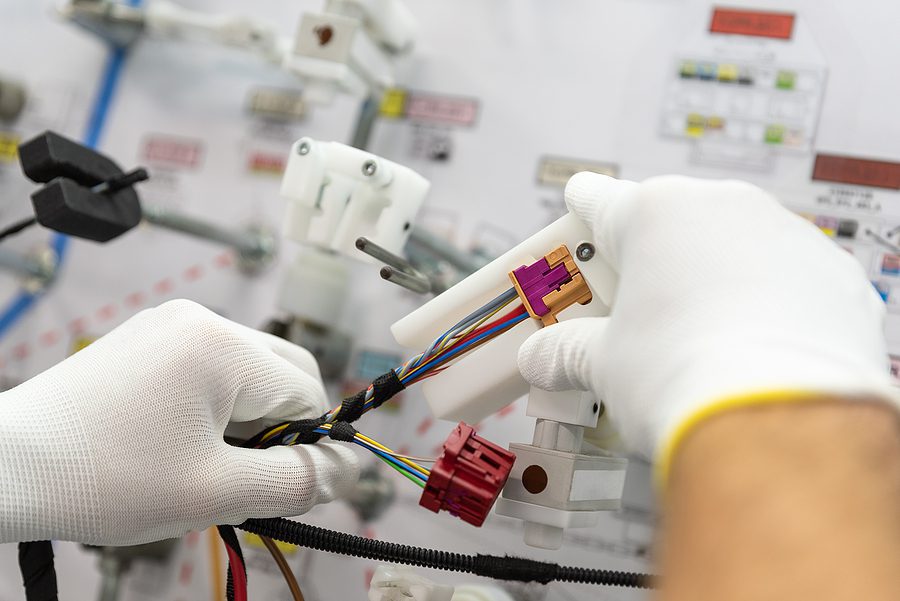

Final assembly is where the magic happens. The prepared wires and their connectors are gathered and crafted into the harness. Each wire will be fed through the harness, taped off, and measured to make sure everything matches the design specifications. A quality cable and wire harness manufacturing partner will ensure that the final assembly is rigorously tested and works to the exact specifications needed for your project.

Finding the right cable and wire harness assembly manufacturer for your next project may take a bit of research and comparing of options. The biggest things to look for are the on-site engineers, the equipment, and the turnkey capabilities that are available to get the project done from start to finish. Before you settle on the shop you partner with, take the time to learn what they can offer you and your project. We’d love to talk with you about your next project. Contact Levison Enterprises for more information about how our capabilities make us the right partner for you and the success of your next build.

Start Your Quote Now!