Quality Assurance Matters When Partnering With an Electronic Manufacturer

More and more companies are turning to outsourced manufacturing to save money and reduce time to market. But outsourcing to an electronic manufacturer should not equal compromising your commitment to quality. Quality control can be a big indicator of whether or not you have found the right company to trust your manufacturing to. After all, quality assurance matters when partnering with an ECM.

Highly Trained Staff with Many Years of Combined Experience

An ECM is only as good as its team. A company that invests in training its employees cares about quality. Furthermore, a company that hires and maintains a top-notch staff clearly knows how to make a good investment.

Engineers In-House

Engineers are an important part of electronic manufacturing. An ECM with engineers on staff clearly acknowledges this.

In-house engineers will be there to oversee the entire manufacturing process from beginning to end. They will catch and correct any potential issues early when they are easier to fix and less costly.

Risk Management Processes in Place

Detecting risks and potential problems before they occur is one of the most impactful things your ECM can do. An excellent risk management plan will detect any issues so they can be corrected before having an impact on the manufacturing process. This will result in keeping costs down, meeting deadlines, and attaining top-quality final products.

Inspections

A hallmark of quality assurance is the inspection process. Inspections are crucial to making sure your product meets quality standards and operates as expected.

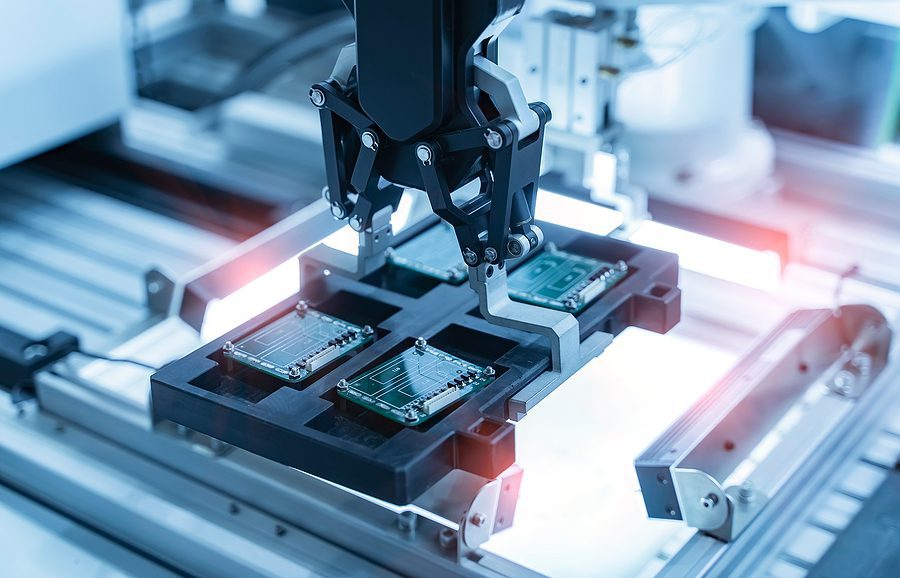

Your ECM may use various methods of inspection. This can range from intense visual inspection to automated robotic inspection, or a combination of inspection techniques in an effort to ensure a high-quality product.

Prototyping and Testing

How will you know if your design even works properly? A quality ECM will offer prototyping and testing services. These are essential steps in the quality assurance process. Prototyping allows for a small run on your device to test its functionality. Then, tests will be performed through assembly and on the final product. It will be put through its paces to ensure it will work properly during its end-use.

Small Batch Runs

There are times when you just need a small production run. A quality ECM will have the flexibility to do a small batch run. And, at the same time, will manufacture you a small number of electronics with the same attention to detail they would give a large order.

Certifications

Certifications are proof that an ECM has a high expectation for quality. Working with a manufacturing partner that has taken the time to earn and maintain industry certifications ensures your electronic project will meet or exceed industry standards. Only certified ECMs will have the space, equipment, and skills required for high-quality electronic manufacturing.

Final Thoughts

Quality assurance impacts every aspect in electronic contract manufacturing. Without it, your final product and your good name could be on the line.

The more complex electronics become, the more quality counts. You need an ECM that recognizes this. Levison Enterprises promotes quality through every step of the design and manufacturing process.

We have strict quality assurance systems in place at every level. We’re an ISO 9001 certified company that continually audits processes and takes painstaking steps to ensure the highest quality in the products we manufacture. Our experts will work hard to make your product the best it can be.

Start Your Quote Now!If you are searching for a manufacturing partner that takes quality seriously, look no further than Levison Enterprises. Contact us today for a free estimate on your next project.