PCB Development in Electronic Manufacturing: The 5 Step Process

Printed circuit boards have come a long way. PCB evolution has led to so much innovation that you can find boards in everything from the simplest electronics in children’s toys to sleek, cutting edge smart phones. But the PCBs for these projects don’t magically appear. There is an entire PCB development process that occurs before you can even start manufacturing the final product, and there could be lots of lag time in between. An electronic manufacturer can help speed up this process.

You see, PCB development doesn’t happen instantly. It takes time. Luckily, there are some foolproof guidelines for preparing your PCB project that could save you time, money, and headaches, and get your product to market.

Design

PCB development is nothing without a great design. First you must decide to design your PCB from scratch or rebuild your current board. Then you layout the new functionality you’d like the PCB to have. Remember, your PCB design must be realistic. Just because it looks good on paper doesn’t mean it will work. This is also where you begin to build your Bill of Materials (BOM.) The BOM is a list of everything that will be needed to build a particular circuit board. Having an accurate BOM will help ensure a smooth transition to manufacturing.

PCB Board Layout

If you’re not an electronic engineer, it’s ok! Working together with an electronic contract manufacturer, you’ll layout your board and get it ready for manufacturing. This is where you will decide where to place components for connectivity. You’ll also do your Design for Manufacturability (DFM) analysis in this stage. A DFM will make sure the parts you require are available and your design meets all the requirements for successful manufacturing.

You can save yourself headaches beginning with this phase of the PCB development process by partnering with an ECM that also has engineering in house. They can troubleshoot any issues discovered with your design and may also have alternative ideas for parts that could save you money on your board. Quality certifications are a huge plus as well. Selecting an ECM who has taken the time and effort to obtain certifications shows they will do everything they can to guarantee the quality of your PCBs.

Prototype and Testing

This phase of the PCB development process is extremely important and should never be overlooked. You want to make sure your PCB functions like you want it to.

Prototyping allows you to see if anything is missing due to parts obsolescence. It also gives you a chance to experiment with changes, like trying a different power source. The PCB will also be put through its paces to see how it will function under ordinary working conditions. In this phase we make sure it all fits and does exactly what you need it to do.

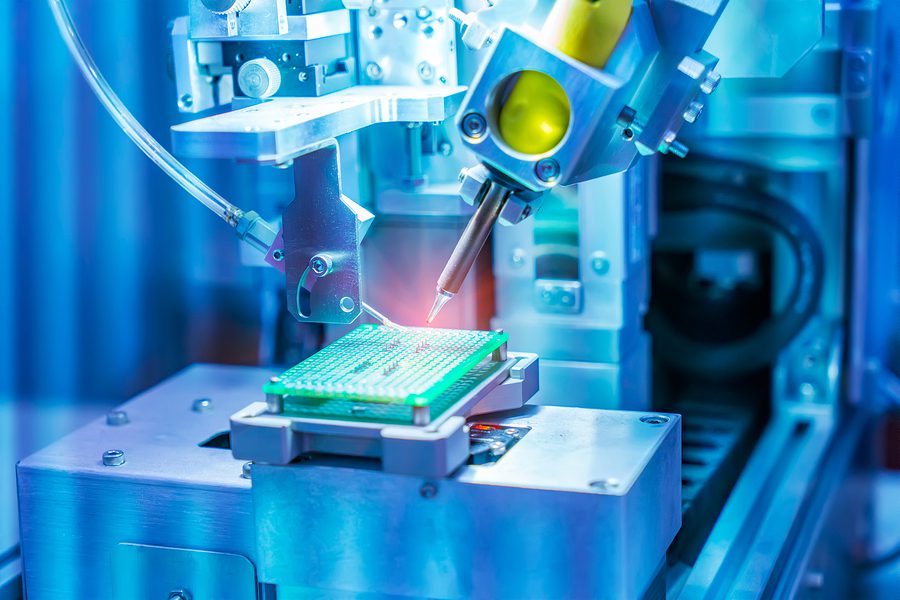

Manufacturing and Assembly

Assembly is the final phase of the PCB development process. Your technical documentation and BOM will guide your ECM along as your boards are produced. During manufacturing, copper will be placed, holes will be drilled, and everything you have planned for will finally come together. It is nice to have an ECM that provides project management so they can take the lead here. They will be in constant communication with you so you can offer feedback and be aware of how the assembly is going.

It is a big bonus if your ECM has testing in house. This means any issues that arise will be detected quickly and changes can be made on the fly if something needs troubleshooting. This will ultimately save you time and money.

Total Assembly

There is one more thing you need to consider as part of the PCB manufacturing process. Does your PCB need to go directly to your customers, or is it part of a larger assembly? Can your ECM take that assembly on? Keeping your total assembly with one electronic manufacturer can reduce errors and shipping delays.

Levison Enterprises is a one-stop-shop for PCB development and manufacturing. We can assist with everything from design and prototyping to assembly and delivery. Our quality certifications show we care about your success. Call Levison today to see how we can help you with your next PCB development project.