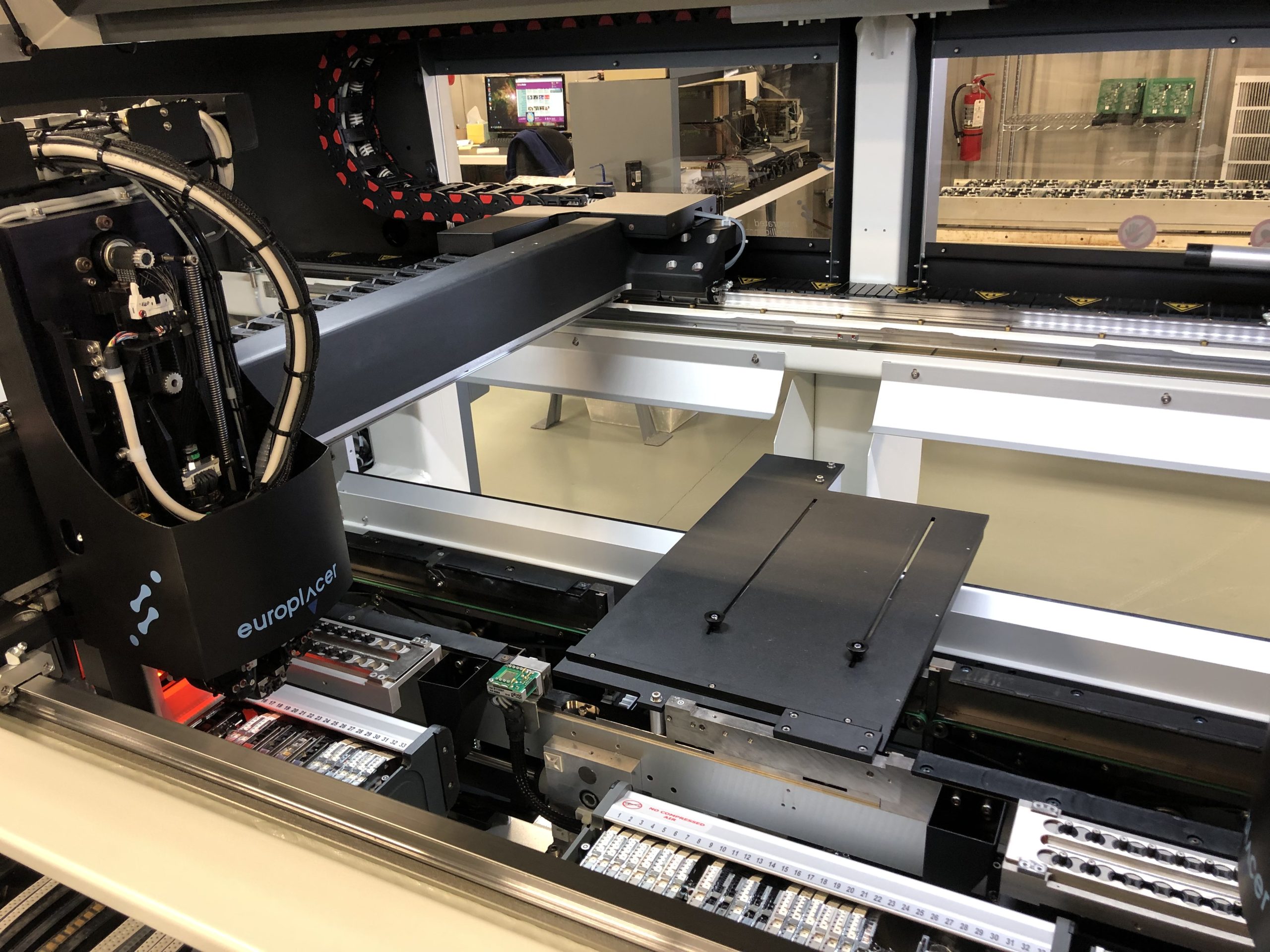

New Pick and Place Machine

If you’ve worked with Levison Enterprises in the past, you know that we are not ones to be satisfied with “good enough.” We are continually investing in the latest safety and quality standards, the best customer service experience, and ongoing education for our team members.

This keeps our processes and our people in the best possible position to fulfill our commitment to our customers for the highest quality products and an exceptional customer experience. The third component of fulfilling this promise is regular investment in our equipment and certifications. This has led us to the acquisition of a new Pick and Place Machine.

This new addition to what we already offer will allow Levison Enterprises to do the same work we currently do, but three times more efficient. And our increased efficiency means an enhanced capacity on the board level for you and your products.

The Benefits of iineo+

The Benefits of iineo+

We are extremely happy to be adding a Europlacer iineo+ to our PCB processing line. Like most of the electronics industry, we’re very familiar with the Europlacer brand. The iineo+ offers increased efficiency, processing of larger board sizes, increased part handling capability and a few more features that we’ll grow into over time.

In addition to greater output, the new Pick and Place Machine is easier to program, diminishing room for errors. It handles board sizes that are three times larger than our current capacity, and can place components that are 01005. These are among the smallest component sizes being placed anywhere right now. This results in a 25% increase in the parts and component types and sizes we can handle for you.

The iineo+ is designed to respond to anything that modern surface mount assembly demands. It’s intelligent features, intuitive user interface, and built-in component testing makes a difference in every board it produces.

Additionally, accuracy and flexibility are the natural results of the iineo+’s platform. It can deploy one or two turret heads, each with its own gantry and digital vision. With eight smart nozzles, the machine produces placement rates up to 30,000 cph. Beyond this, feeders can be positioned in the front or back of the machine or both. These and other flexible options provide exceptional capacity that can work with a range of jobs.

Further, this kind of technology, with such accuracy and options, allows Levison Enterprises to more accurately quote your jobs and gives us additional solutions to your electronic projects.

Training and Expertise with the iineo+

Training and Expertise with the iineo+

However, it’s never just about new machinery. We are only as good as the people who program and manage the equipment so with this new investment comes new employee training. The software and technology involved with the new Pick and Place Machine make it easier to program, but, as always, we want to make sure our people know the best ways to build efficiency and quality into your PCB project.

This investment will also result in increased streamlined programming, reducing potential errors and project timelines in your electronic assembly.

New Pick and Place Options with Levison Enterprises

We are excited to add this robust new piece of machinery and expertise to our lineup of offerings. We strive for a continued focus on quality products, superior customer experience, and efficient production. We invite you to explore the options that our new pick and place machine can provide for your next PCB project.

Email Sales