Is a Custom Designed Printed Circuit Board Right for Your Project?

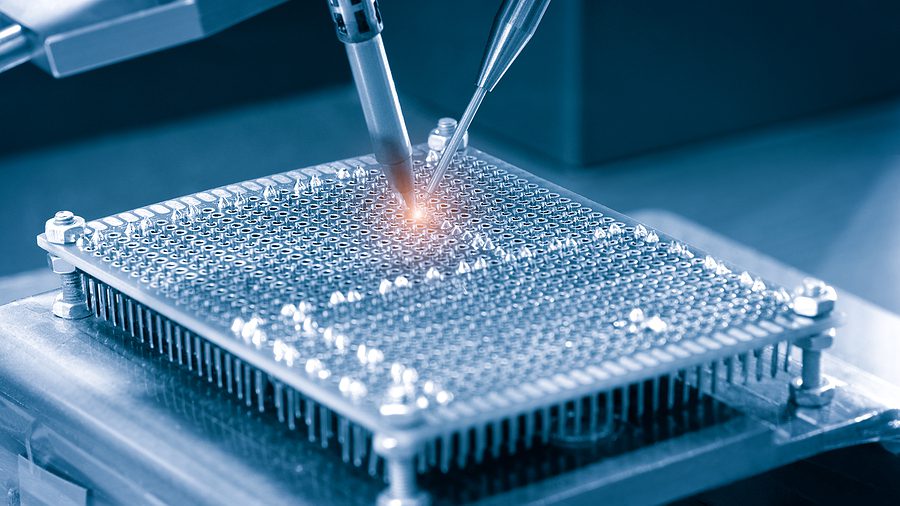

Buying off the shelf electronic components can work for certain projects, but designing a custom printed circuit board (PCB) may be right for others. A custom PCB gives you the opportunity to take your project to the next level and ensure that it is the right fit for your product. Finding the right partner for outsourcing is the next step in the process.

When Should Your Electronic PCB Be Custom Made?

There are a few instances where your PCB should absolutely be custom made.

- Your PCB is highly complex

- You need a large volume of complex PCBs

- Your PCB will be mission-critical

In these cases, a full-service electronic contract manufacturer (ECM) can put their in-house engineering team to work to produce everything that goes into the PCB, including PCB assemblies, box builds, and cable assemblies. Outsourcing custom PCBs to an engineering design group allows you to create a board that matches your design, rather than trying to fit your design around a prefabricated board.

What Factors Go into a Custom Electronic PCB?

A custom printed circuit board has four phases in the process. The engineering design team you choose will develop the scope of work and pricing based on the specifications you need for your requirements, but all projects will go through:

- Design

An ECM partner with on-site engineers will be able to take your project through a custom design process, including an assessment of where your concept may lack important aspects. If you already have a custom design, an ECM partner can still use their skills to assist with the process.

- Testing

Your ECM partner will design a custom test fixture and procedure for your custom PCB if it is necessary. Depending on the project, the PCB will have requirements to meet and custom testing will ensure that this can be done.

- Prototyping

This is where the engineers will work out all the kinks in the design before handing it off to production. If your company has already developed the thorough design, this is where the partner can pick up. Prototyping before manufacturing is a crucial step for a quality end product.

- Manufacturing

Once your product has been through design, testing, and prototyping, manufacturing will begin. In the case of a custom PCB, the team has been working closely with you prior to this step. Everything will be reviewed with your team, along with design-for-manufacturing and product release plans.

Finding the Right Engineering Design Group for Your Project

The key to finding the right engineering design group is to find a partner who is able to handle the complexity of your project and will not discriminate based on the size of your project. The right group should be a turn-key facility with on-site engineers who can see your project through from design to delivery.

Your commitment to quality, complexity of design, and the budget for your project will determine your need for a custom PCB design, and finding the right partner will help you decide if it is the right choice for each unique project. Finding the right engineering design group and ECM to partner with will lead your project in the right direction. Contact Levison Enterprises today for more information about our design capabilities.

Start Your Quote Now!