How your BOM Can Affect the Success of Your Next PCB

Your BOM can impact your entire project, and that includes impacting it in both a good or a bad way. A complete, specific, and comprehensive BOM will keep everything on track. However, if you are missing anything from your BOM, you could face costly delays and even risk product failure. Component shortages are still challenging, so a thorough BOM will allow your ECM to adapt accordingly to get you everything you need. When times are already stressful for electronic manufacturing, it is important not to cause a delay by something you CAN control.

Your BOM Should Start with the Schematic

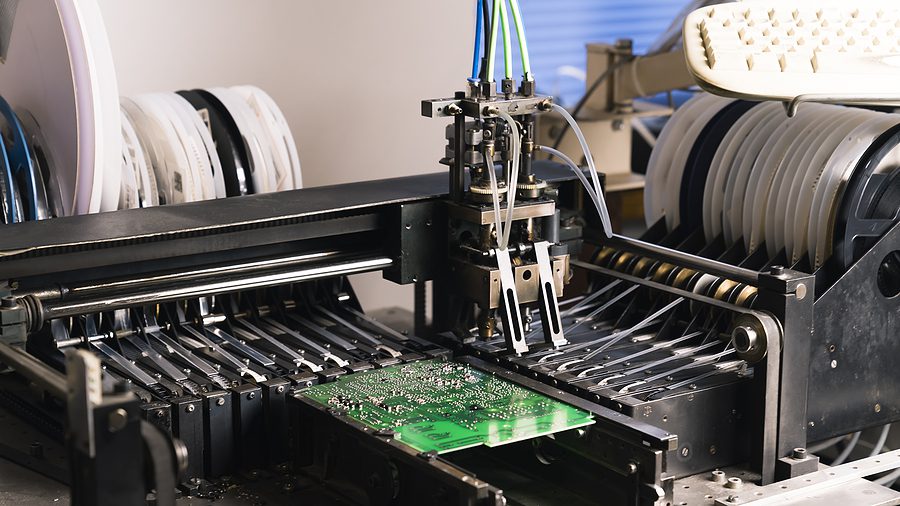

For a PCB, you’ll start with the schematic illustrating a circuit. That circuit will be made with components that you need for the design. These basic circuits will then become the printed circuit boards used in the final product. Common symbols define the type and circuit elements that an engineer uses to realize the designs. These symbols will then evolve to become the unique components in your enterprise library. You’ll use something like letter designators from the drawing and make a list of each piece as it corresponds to the drawing. After this, you’ll research various suppliers for material and pricing options.

Include Materials and Enterprise Part Numbers

Once the schematic is complete, you are ready to choose hardware. Working from a BOM, the engineer will select the vendors who make the parts and components you need. This process requires a collection of datasheets, assigned enterprise part numbers, and load vendor information. Each component symbol with the enterprise part number will be part of the PCB library. When you know the vendor, you will get the exact dimensional information. With all this information, you will have confidence in ordering all the components necessary for manufacture.

For Easy Procurement, List the Real Hardware on the BOM

With the current supply shortages, your ECM will likely need to shop around for the components needed. With a complete BOM, your ECM can easily track exactly what parts are being sourced and from which vendor. All the comprehensive information will be in one place for both you and your ECM partner to track.

Working Without a Comprehensive BOM

You may think that this level of detail is overkill. You know approximately what you need, so a simple list should suffice. If your ECM has the vetted suppliers, they’ll be able to get what you need. This simply isn’t the case anymore. Supply chain issues have put a real strain on manufacturing, PCB assembly, and all products related to consumer electronics. To get things done in the most efficient and cost effective way, you need to be as clear and thorough as possible. Without a thorough BOM, you may find yourself missing key components that are in short supply, which will then cause delivery delays, manufacturing delays, and ultimately, unsatisfied customers.

Making a list is simple. But you need more than just a list for designing and assembling PCBs. The more comprehensive your BOM is, the more useful it is for your ECM. Including all necessary information, every component, and specifics about each material makes it the most useful for a successful assembly. Updating the BOM as necessary will keep everyone on the same page for the easiest management of the product throughout its lifecycle. Levison Enterprises has been a trusted source for PCB manufacturing and assembly, and with our continued commitment to excellence, we can help your product succeed. From design support to fulfillment services, we truly are a one-stop-shop. Contact us for a quote on your next project.

Start Your Quote Now!