Design Considerations for Military and Aerospace PCB Assembly

In today’s technologically advanced world, almost everything is made better, smaller, and more durable through the use of printed circuit boards, or PCBs. You’ll find them in televisions, computers, stereos, digital clocks, microwaves, and even cell phones.

Of course, PCBs are also found in both military and aerospace applications. When used for these applications, there’s a high standard that PCBs are held to. That’s because PCBs for military and aerospace have to do more than the average PCB. For military and aerospace electronic equipment, PCBs need to be manufactured to withstand extreme environmental conditions.

Advantages of PCBs

At the heart of our technological revolution is, literally and figuratively, the PCB. These thin boards are made of insulating material, with a metal-coated surface. Etches are made into that metal surface to allow electricity to travel throughout the board to the different components that are surface-mounted or attached through the board.

Resistors and capacitors can be inserted and soldered together through automation, making PCBs ubiquitous and economical.

What Separates Home-Use PCBs from Aerospace and Military PCBs?

Understanding the need for a higher grade of PCBs comes from knowing what aerospace and military PCB assemblies get used for.

- Satellite equipment

- Electronic flight instrumentation systems

- Robotic systems

- Unmanned vehicles

- Ruggedized computers

- Base/camp security and protection

Simply put, the types of PCB assemblies manufactured by a company like Levison Enterprises for the military or aerospace industry must be designed to withstand the harshest environments on this planet. They also must be ready to perform when duty calls, with no chance of failure. When producing PCBs for military and aerospace applications, they must be produced within one to two percent of tolerances. The PCBs you’ll find in commercially available products only need to fall within five to ten percent, by comparison.

How does Levison do that? First, they must be held to the highest design and manufacturing standards possible, like AS9100, which sets them head and shoulders above the competition. AS9100 sets the standard for the creation and maintenance of supplying the safest and most reliable components available.

What Sets Levison Enterprises Apart?

In addition to meeting and exceeding the highest design certifications for military and aerospace PCB assembly, it’s the people who work here that make the difference.

Our design team has decades of experience designing and implementing PCBs for a number of applications. We bring this expertise to every project we take on. When you work with Levison Enterprises to design your military and aerospace PCB assemblies, you can rest assured knowing that the technology we create will meet your exact standards.

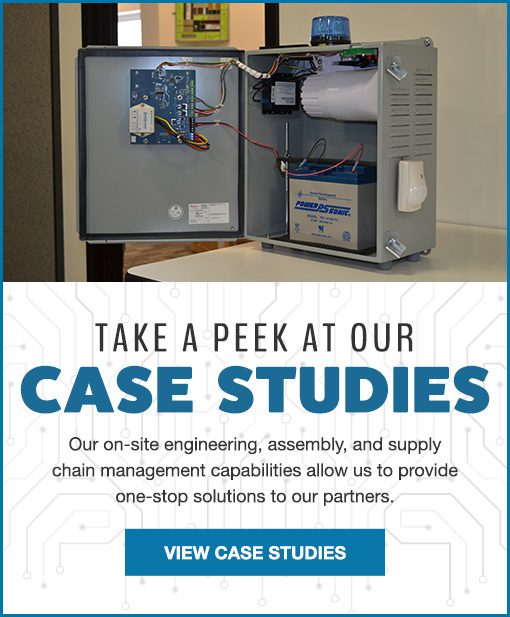

Levison Enterprises also handles everything in-house. There’s no risk of getting PCBs manufactured with third-party, counterfeit parts. From design through delivery, Levison is committed to delivering for you, on time and with the highest quality.

We’ve fulfilled numerous assembly contracts for the FAA, Department of Defense, and many other government entities. There’s no doubt Levison can handle the most complex and sensitive PCB assembly considerations.

To learn more about what sets Levison’s reliable turnkey electronic assembly design considerations apart from our competitors, contact our team today. We’re confident you’ll come to rely on the Levison Enterprises team for your next military and aerospace project.

Email Sales