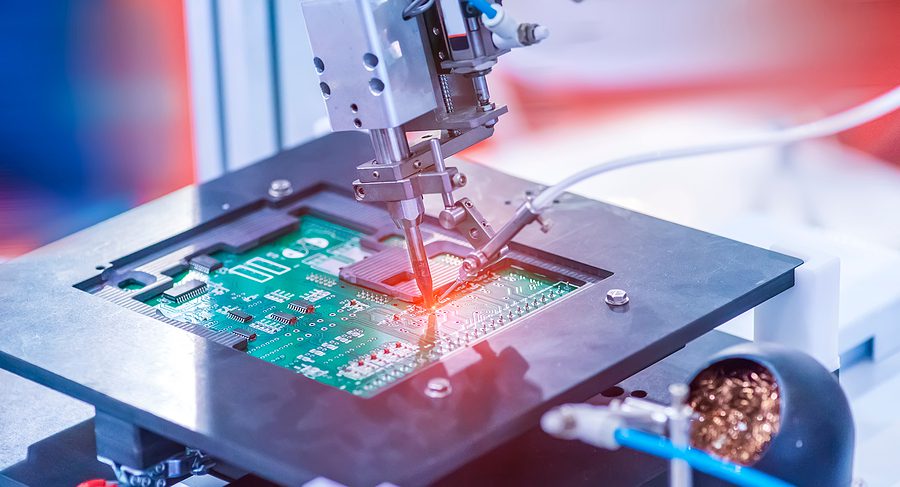

Choose an Electronic Manufactrer with Strong PCB Assembly Quality Control Standards

A top priority when choosing an ECM is quality control. When you choose an electronic manufacturer with strong PCB assembly quality processes in place, you know you are choosing a partner who will help your company’s overall success.

Highly Qualified and Certified Engineers on Staff

The ECM depends greatly on their staff. Engineers provide the knowledge and expertise for streamlined designs, can prevent problems before they arise, and will create a higher quality product. The value they add can’t be equaled. Check with the ECM about the engineers on staff, as well as specific certifications, experience, and awards they may bring to the table.

Risk Management Process Early in Assembly

Keeping costs down depends on mitigating risk. Risk management early in the process will also help in meeting product deadlines and achieving better final products. When you catch potential risks and issues before they impact production, you save yourself many headaches and additional costs down the road. A good ECM should have a comprehensive risk management plan which starts with risk assessment early in the process.

Certifications are Crucial in PCB Assembly Quality Control

Holding a certification for a specific job is very helpful for PCB assembly quality control. It means that the employees are up to date on all current requirements and standards and have extensive technical expertise for their role.

Continuous Improvement Strategies

You can tell how much a company values quality control by how much importance is put on continuous improvement. Companies should be striving constantly to keep up with industry standards, improve their processes, and increase their customer satisfaction.

Testing

Testing is a crucial part of PCB assembly quality control. Testing and inspection should always be part of the process for the ECM you partner with. Nothing should be left to chance, and testing throughout the process will ensure that the final product is up to standard. Some of the checks throughout the process are:

- Design for Manufacturing (DFM)

The design file is checked against the ECM’s equipment constraints. Most violations need to be corrected before the board can be constructed.

- BOM Validation

These are checks to ensure the components in the BOM match the PCB design.

- Manufacturer Part Number (MPN) Verification

MPNs may be incorrect and can result in the acquisition of the wrong component. A single incorrect digit may result in a wrong package type, and this error can result in lost time and additional costs.

- Component Reference Designator Verification

This is the unique identifier in the BOM. If incorrect, the number of components acquired may be incorrect as well.

- Component Manufacture Status Checking

This ensures that the component will be available for future production.

Start Your Quote Now!Before choosing your ECM, check for quality assurance processes and make sure that the ECM you choose to partner with has the same high standards as you do. Proper quality assurance processes are the key to a successful product, and a successful partnership. Contact Levison Enterprises to learn more about how our turnkey certified services can make a positive impact on your next project.