Capabilities Important to Successful Medical Device Manufacturing

Medical devices are challenging and complex to produce. The combination of regulatory requirements and critical life-saving components make the development expensive and technically difficult. A domestic turnkey medical device manufacturer with experience, certifications, and advanced capabilities is your best ally to address common pain points in medical device manufacturing from supply chain issues to faulty products.

Design Services

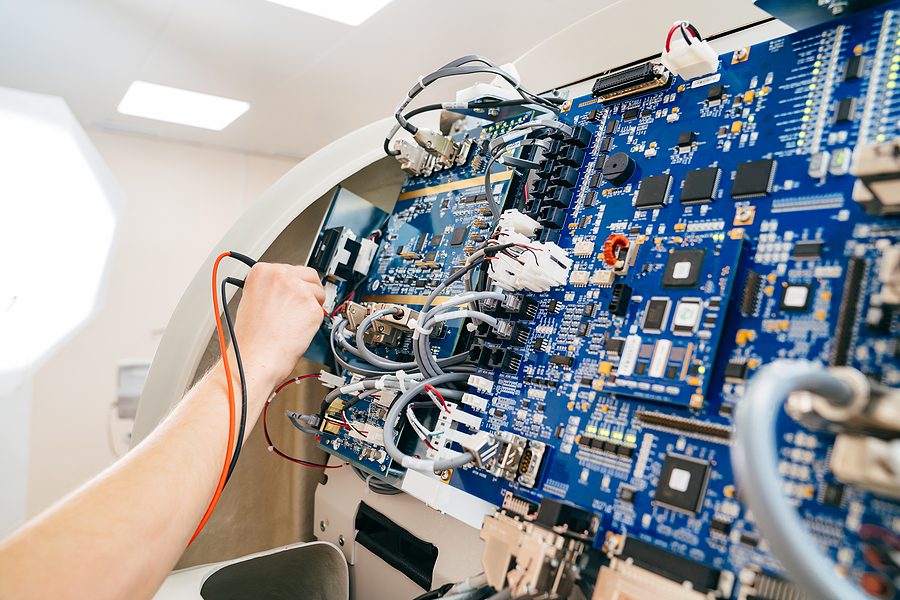

Look for an ECM offering PCB design services as not all ECMs provide this invaluable service. An experienced turnkey ECM who provides in-house design and on-site engineering teams focuses on collaboration with clients to create functional, efficiently designed electronic products. They offer robust design capabilities using the latest cutting-edge software, applications, and equipment.

Certifications and FDA Registration

ISO 13485 is one of the most stringent standards for medical device designers and manufacturers. This standard defines a broad range of requirements on quality management systems (QMS) for medical devices and equipment. Since the medical device industry is highly regulated, OEMs need assurance that their new products will be in full regulatory compliance once their product hits the market. Therefore, it’s critical to find an ECM partner that is ISO 13485 certified by NSF-ISR and FDA Registered.

Industry Knowledge

Finding the right ECM partner means finding a facility with the right people working with the right equipment. A quality ECM has engineers with experience in medical device manufacturing and the certifications to back it up. A good ECM has continuous improvement practices in place for their staff and equipment, and can offer assurance they can handle your design.

Turnkey ECM

One of the many benefits of working with a turkey domestic ECM partner is the element of only having to work with one project manager. Having only one point of contact to service all your needs means you can pick up the phone and have your questions and concerns addressed more efficiently and effectively.

Domestic ECM Partner

Outsourcing overseas may look like a cost-effective choice, but outsourcing internationally can mean slow communication due to time zones, possible language barriers, no definitive IP protection, and shipping delays. Choosing a domestic, turnkey ECM partner means the entire process is handled by one partner, and that partner can easily communicate with you throughout the process. A domestic partner understands the high regulatory requirements of medical devices, and a turnkey facility significantly reduces the risk of any errors that come with moving your product through different stages and locations. When you work with a domestic turnkey facility, they’ll handle the entire process from design through delivery.

Vetted Supply Chain

A vetted supply chain is essential in all PCB manufacturing, but in medical device manufacturing, the need for high quality parts is even more vital. For a medical device to meet industry standards, the risk of counterfeit or obsolete parts must be mitigated. Choosing an ECM with a vetted supply chain ensures your design will move through the manufacturing process with the proper parts from reliable suppliers who provide legitimate and quality components that meet the strict regulatory medical device standards.

The best way to ensure your business is avoiding counterfeit electronic components is to work with an ECM with an established mitigation process in place. A reliable ECM partner can help you avoid counterfeit electronic components.

PFMEA in Place

Process Failure Mode and Effects Analysis carefully analyzes and identifies any potential errors that could go wrong during the manufacturing process, helping electronic manufacturers build in safeguards so they can plan for potential failures for every scenario. It also helps avoid errors during changes in an existing manufacturing process, when using new technology and equipment, or when relocating to a new facility, The PFMEA method gives electronic manufacturers the ability to plan for potential failures and put preventative measures into action, saving you time and money.

Engineers Onsite

Onsite engineering is extremely essential and beneficial for your medical device manufacturer. Troubleshooting can occur at any point during production, giving them an opportunity to identify errors and solve them quickly. Identifying problems early in the process makes for a more streamlined, corrective process. On-site engineers are essential for quality assurance as they provide necessary knowledge and expertise to improve designs, prevent problems, troubleshoot, and ensure a successful finished product.

Packaging, Shipping, and Fulfillment Services

Partnering with an ECM offering product fulfillment services, including direct shipping to the distributor, saves you time and money. Transitions can be a pain point for many projects, where costs due to delays or damages can be outrageous. Packing and shipping services usually require the support of a subcontractor, but a quality ECM partner can handle the packaging and shipping process for you.

Choose an Experienced, Domestic Turnkey ECM

Levison Enterprises is your one stop shop for medical device manufacturing. With decades of experience in a wide variety of industries including medical device manufacturing, we know we can help you build a better product. We are ISO 13485 certified by NSF-ISR and FDA Registered, and our vetted supply chain coupled with on-site engineers can help mitigate common delays in PCBA and manufacturing. Contact us today for a quote.