Build Efficiency Into Your Project with an All In One Electronic Manufacturing

No matter what you’re looking to manufacture, you’re looking for efficiency. An all-in-one electronic manufacturer means cost savings and high-level quality for your project.

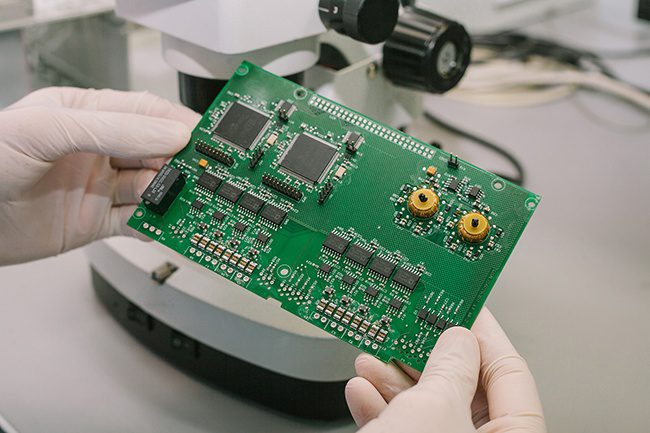

Circuit boards, cables, and cabinets alone accomplish nothing. When we put them all together, we get smart, technical electromechanical products that serve your company’s goals.

There are many paths to get those boards and cables assembled. The most efficient is the box build, which assembles your entire product under one roof, eliminating many sources for mistakes and delays.

An all-in-one ECM takes the box build and squeezes yet more efficiency out of it by targeting shipping and lag times that can plague standard box builds.

Production Costs

Prototyping – Mistakes that surface after a project is in production are much more costly than sifting them out before production. Costly production mistakes can be mitigated with thorough prototyping.

Your all-in-one ECM brings cost savings to your project by offering rapid prototyping. Cutting edge technology, especially in the area of 3D printing, has decreased the cost and time of prototyping, allowing you to work with your all-in-one ECM to inexpensively work out the kinks in your project. This saves you time and streamlines your production process.

Parts & Materials – Once you know what parts and materials are going into your project, an all-in-one ECM can help you source each piece through its network of partner vendors. From a production standpoint, you gain advantages in knowing the quality and performance of your parts. From a cost standpoint, you gain potential savings through your all-in-one ECM’s relationships, bulk purchasing and buying power.

Communication savings – Lack of communication and miscommunication are easily among some of the biggest areas of potential loss for your project. When a project needs to move between different vendors, any breakdown in communication can mean expensive delays, or worse, backward progress. When there is no need for a project to move between vendors, this cost is all but eliminated. An all-in-one ECM builds efficiency into your project just by being a single point of communication.

Packaging and shipping efficiencies – Transitions tend to be a pain point for all projects. The transition to your consumer is potentially the most painful, where the costs of delays and damages are inflated.

Packaging and shipping are the steps that always need support from a sub-contractor. However, a good all-in-one ECM partner will be willing and able to relieve this headache for you.

Your all-in-one ECM knows your build and its specs. They also know the regulations and shipping methods that will work best for your product, and they know what the shipping company needs to do its job. A good all-in-one ECM knows how to work with shippers to help you achieve low-cost, high-quality shipping solutions for your products.

Highly Trained Employees

At an all-in-one, ECM, training, and certifications are given high priority. Since the quality of your product reflects directly back on the quality of the ECM, having highly trained employees is of utmost importance.

The all-in-one ECM will have a diverse portfolio of projects and matching expertise on the team. In order to maintain highly-skilled expertise in a wide range of projects, all-in-one ECM employees will regularly engage in the latest training. This keeps them nimble, innovative and capable of working on all kinds of projects from Aerospace and Medical to Government and Food Safety.

Along these same lines, technical training is not the only kind of continuing education you should expect from an all-in-one ECM’s employees. Quality certifications are equally important.

The level and type of certifications your ECM maintains speak to how dedicated your ECM is. It’s easy for an ECM to say they are committed to quality. Demonstrating that commitment through high-standard certifications is another level of commitment. Quality certifications require continuous audits and training to maintain. They call for highly qualified staff that are dedicated to your project. Regardless of your project’s specific certification requirements, you should require this level of integrity for your project.

Highly trained employees aren’t just nice to have, though. They mean you’ll have a stronger, smarter project. Your build will be leaner and experience fewer mistakes. Fewer mistakes mean fewer delays, which saves your project money.

Project Familiarity

Wouldn’t it be nice if you could take everything you know about your project and place it into the manufacturer’s head? With an all-in-one ECM, you get about as close to osmosis as possible (without the weird, mind-melding parts).

Your all-in-one ECM knows every single piece and part of your project. They aren’t making a single widget that’s going to eventually go into some invisible product. They are making your product, from start to finish. They know you and they know your project, sometimes even better than you!

That familiarity feels nice but more importantly, it drives productivity and efficiency. Tracking down issues becomes a quick in-house discussion and fix. Making an 11th-hour change can be done without re-engaging other vendors. Repairs are easy to source and complete.

All of this knowledge and experience with your project is an investment in an efficient overall product.

Levison Enterprises is your all-in-one ECM for your Industrial, Government, Mobility, Aerospace, Medical, and Food Safety box builds. Contact Levison Enterprises today to learn more about how we can partner together on your next box build.