BOM Management is Key to Successful Electronic Manufacturing

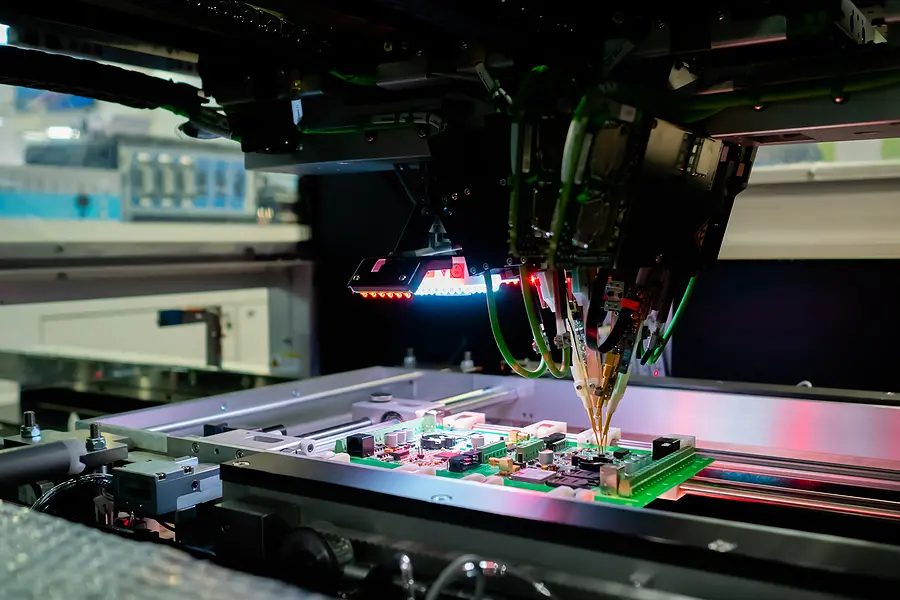

The bill of materials (BOM) is essential in the design and production phase of electronic devices, starting with printed circuit boards (PCBs).

A BOM is like a recipe listing all the items your manufacturing partner will need to build your product. Partnering with an electronic manufacturer with design support is extremely helpful and can make a difference in your time to market. Before submitting your BOM to your ECM, you want it to be up-to-date, accurate, very detailed, and not leave room for potential misunderstandings. An accurate BOM can save you time and money. Inaccuracies will lead to complications in manufacturing and unnecessary delays.

Having a standard set for BOM management can lead to successful manufacturing. Although the information may differ from project to project, there is some basic information that must be present on each column of the table, including:

Part Number

The part number is the code, also known as the MPN (Manufacturer Part Number), provided by the manufacturer to identify each part. Since the part number contains a unique code used internationally, there’s no risk of confusion or misunderstanding between those compiling the list and those using it.

Manufacturer’s Name

This field details the single part, allowing BOM users to directly access the manufacturer’s or distributor’s catalog, identifying the part immediately and accurately. For those compiling the BOM, this information is critical as it’s necessary to verify, in advance, that each part is available in the required quantity, ensuring it can be found at a cost and at a time compatible with the project budget. Otherwise, a replacement must be found, involving additional time and costs.

Description

The description provides additional information on the part, including color, weight, size, units of measurement and electrical characteristics (voltage, current, power). The description helps to better describe each part in detail.

Quantity

Quantity specifies the number of units for each part required by the PCB design. In the case of large-scale production (exceeding a few thousand units) discounts obtained from the manufacturer should be noted.

Reference

Each part of the PCB must have a unique reference (usually matching the PCB silkscreen) allowing the identification of where the part will be positioned on the printed circuit (for example, R1, R2, R3, etc. for resistors). The reference, typically composed of a letter followed by a progressive number, also matches the information in the schematics.

Mounting Type

For many electronic components, the distinction must be made between surface mounting (SMD) or through hole (PTH).

Package Type

When applicable, the specific package used by the part shall be specified (e.g. QFN16 or 20-SSOP).

Number of Layers

With the proliferation of multilayer boards, it’s essential to specify which layer the part belongs to.

Alternate Part

If a part can easily be replaced without affecting the PCB design, it’s possible to indicate an alternative part to be used if the original part is no longer available.

BOM Level

Typically, the bill of materials is organized on several levels, each identifying a specific assembly or a sub-assembly. The level indication allows easy navigation across the various BOM levels. A multi-level BOM is also referred to as hierarchical, while a single-level BOM is called flat. For example, a smartphone consists of a SoC, display, memory, sensors, camera, wireless interface, connectors, screws, and small parts, and more. Each of these sub-assembly could have a dedicated BOM.

Phase

The phase field indicates at which stage of the project life cycle each specific part is used. For example: in production, during development, not released, to be approved, etc. This information is particularly useful for highly innovative (NPI) projects, as it allows one to easily track progress, creating a realistic project schedule.

Additional BOM Notes

When providing the BOM for your PCB design, manufacturing, and assembly, it is crucial to ensure it is thorough and accurate. When you provide a complete BOM, you are giving the best possible information to your ECM and developing a quality partnership. If you’re unsure about whether you have all the information necessary in your BOM, contact Levison Enterprises. We have vast industry knowledge, a vetted network of reliable, quality suppliers, and in-house expertise to give your product a competitive edge. Contact us for a quote on your next project.

Start Your Quote Now!