Benefits of an Electronic Manufacturer Partnership

Companies are always looking to get an edge on the competition and improve their bottom line. As technology evolves, you may not have the proper resources you need to competitively get a new product from concept to market. You may need to consider turning to an outside electronic manufacturer.

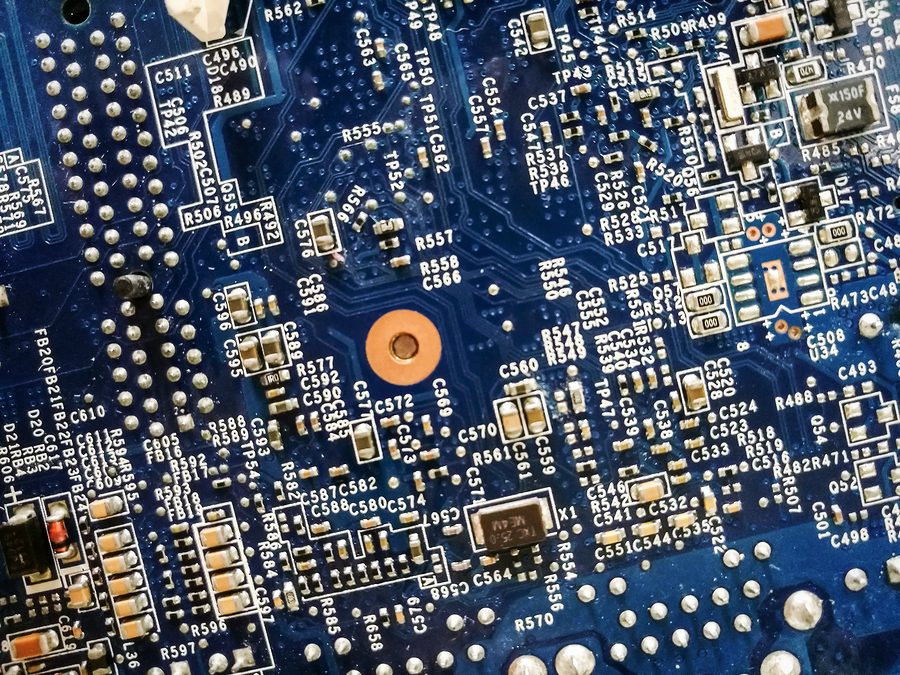

Electronics manufacturing services (EMS) refers to companies that design, manufacture, and provide other services for electronic components and assemblies to original equipment manufacturers, like you. You’ve already invested a lot of time and energy into your project. While there may be some trepidation in trusting it to someone else, there are many benefits of outsourcing your electronics manufacturing and assembly to an EMS manufacturing partner.

Save Money with EMS Manufacturing

The top reason most companies consider an EMS manufacturing partnership is to, quite simply, save money. Some industries are able to cut production costs by as much as 35% with the right contract manufacturer. The contract manufacturer already has manufacturing infrastructure in place, so there is no cost for facilities, equipment, or technology. They also have flexibility in terms of scale and can do limited runs, as well as prototyping.

In addition, your EMS partner already has a vetted supply chain. You will get the advantage of an existing relationship with trusted vendors who provide top-quality materials at the best price.

Testing In House

You need to be able to trust your product will work just the way it needs to when it gets into the hands of your customers. Working with an EMS partner with in-house testing will give you that peace of mind. Your product will be tested throughout the manufacturing process in order to detect and reduce production errors. Multiple testing cycles and experiments will guarantee it will function properly and will continue to do so during its real-world application.

Engineering on Site

So, who is keeping an eye on your product during production? Who fixes problems when they arise? A manufacturing partner with on-site engineering lets your know someone is always on the lookout for issues that could compromise your product’s performance. If something is detected, on-site engineers can respond and correct it immediately. They may also identify areas that need improved or could be streamlined. Changes they make early in the production process can save you valuable time and money in the long run.

Turnkey Services

At times, you might need an EMS partner to complete an entire project, from design to shipping, and everything in between. Perhaps your team is busy on another project. Or, maybe your amazing concept is a little out of your area of expertise. An EMS partner with turnkey services will be able to take care of everything for you in one shot. Like a true team, you will work together to get the job done without sacrificing the quality your company is known for.

Levison Enterprises is ready, willing, and able to become your choice for an EMS partnership. Your partnership with Levison comes with a guarantee. We guarantee your project will be completed with the greatest attention to details and quality. And we guarantee you will be pleased with the result. Contact us today to find out how Levison Enterprises can turn your drawings and plans into a prototype that is ready for full production.

Email Sales