Benefits of an Electronic Manufacturer with Redesigning Capabilities

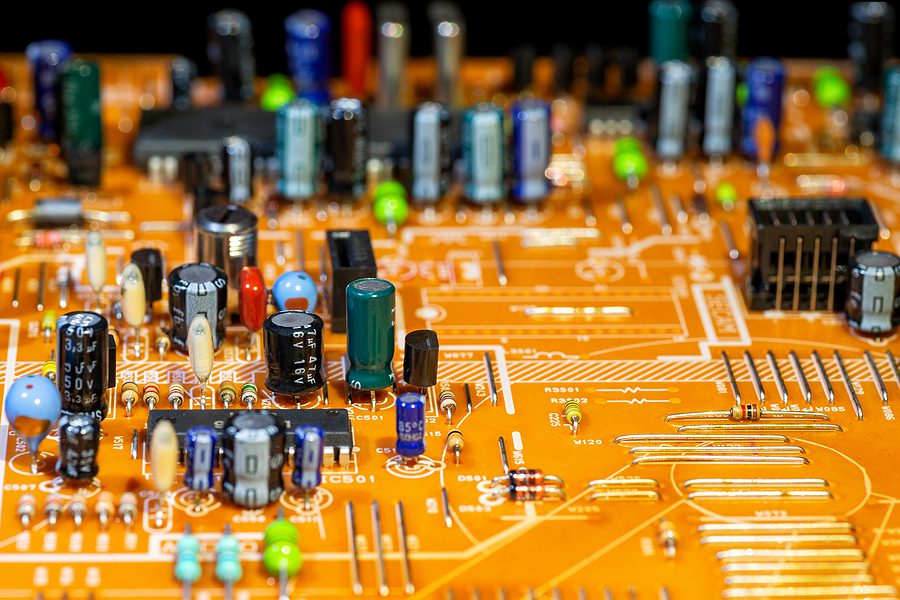

An electronic contract manufacturer with redesigning capabilities just might be the electronic manufacturer of your dreams. They can not only take a lot of work off your hands but can help take your project to the next level by upgrading and developing solutions to any flaws. From revamping a legacy product to replacing obsolete parts, an ECM with redesigning capabilities will prove invaluable to your PCB assembly.

Engineers In-House

When you partner with an ECM, you count on them to make your project a priority. An ECM with in-house engineers means you will have experts on standby as soon as a redesign is needed. They will be watching the entire PCB assembly and manufacturing process and will step in quickly if issues are spotted.

Redesigning for Parts Obsolescence

Technology changes rapidly. PCB components may even become obsolete in the short amount of time between design and manufacturing. In these instances, in-house engineers can quickly redesign using current components.

Troubleshooting

On-site engineers provide your PCB assembly with a team of troubleshooting experts. They continuously monitor and test your project in order to uncover issues and promptly redesign before potential problems have a chance to cause major setbacks.

Streamline Design for Better Functionality

In-house engineers have the added value of optimizing your project. They will offer engineering solutions to streamline your design for better functionality while satisfying your requirements for quality, reliability, and cost.

Reverse Engineering

Designing and manufacturing electronics does not require reinventing the wheel. Reverse engineering can play a vital role in updating a legacy product, battling parts obsolescence, or redesigning for optimization. Working with an ECM who has the ability to use reverse engineering allows your PCB designs to be upgraded with little to no interruption in the manufacturing process.

Reverse engineering is the process of deconstructing a product to extract design information. Engineers perform a detailed examination of its composition in order to redesign with the same form, fit, and/or function. Applications may include:

- Upgrading legacy systems

- Design for Manufacturability (DFM) analysis

- 3D prototyping for rapid product development (RPD)

Electronic companies can typically push even better products to market utilizing reverse engineering.

Design Support

Things can sometimes fall between the cracks when you work with multiple companies to encompass your product designers, engineers, and manufacturers. Working with an ECM who has redesigning capabilities will give you the design support you need for your PCB assembly. This support can optimize manufacturing and accelerate product development cycles. Companies that collaborate are the companies that get ahead.

At Levison Enterprises, we provide expert design and engineering support, robust quality assurance measures, and state-of-the-art technology. We are a full-service design to build manufacturer with redesigning capabilities. We’ll take your ideas or designs and turn them into a finished quality product.

Don’t trust your PCB assembly to just anyone. Levison Enterprises is a manufacturing partner who will be as invested in your project as you are. Contact us today to learn more about our capabilities. We look forward to assisting you with your next project.

Start Your Quote Now!