Avoid Counterfeit Electronic Components in Medical Device Manufacturing

Avoiding counterfeit electronic components is always important, but when these components are being used for medical device manufacturing, the need becomes even more crucial. If fake medical devices are on the market, it poses a danger to public health and patient safety.

What is a Counterfeit Electronic Component?

A counterfeit electronic component is an unauthorized copy, imitation, or modified electronic component that was knowingly presented as a legitimate component. It can also be a used component that has been altered and misrepresented as new without disclosure.

What is at Stake with Counterfeit Electronic Components

Counterfeit parts often don’t meet the required electrical safety precautions or the minimal specifications. Because of this, they can pose serious threats to those using these devices. Counterfeit parts risk product malfunction and failure. They will not work as designed and can pose a financial risk to your business. Beyond the financial risk, counterfeit parts can also pose real dangers, including:

- Short circuit

- Electrical Shock

- Fires and explosions

- Equipment failure

In medical devices, these risks are even higher. It is crucial to choose an ECM who is focused on avoiding counterfeit electronic components and certified in compliance standards like ISO 13485.

How ECMs Help with Avoiding Counterfeit Electronic Components

Counterfeit parts can be difficult to distinguish from the real components, especially to those who are unfamiliar with the parts in question. Counterfeiters often have excellent websites with convincing photos and are able to mimic the product packaging. The scarcity of parts can also contribute to the use of counterfeit electronic components. The best way to make sure your business is avoiding counterfeit electronic components is to work with an ECM who has a mitigation process already in place. Reliable ECMs can help with avoiding counterfeit electronic components by:

- Working with OCMs-Purchasing parts directly from the original component manufacturer is a reliable way to ensure that you are using legitimate parts. If the parts haven’t passed through anyone else, it’s unlikely they were tampered with.

- Using Vetted Suppliers-If you can’t buy directly from the manufacturer, having a vetted supplier is the next best thing for avoiding counterfeit electronic components.

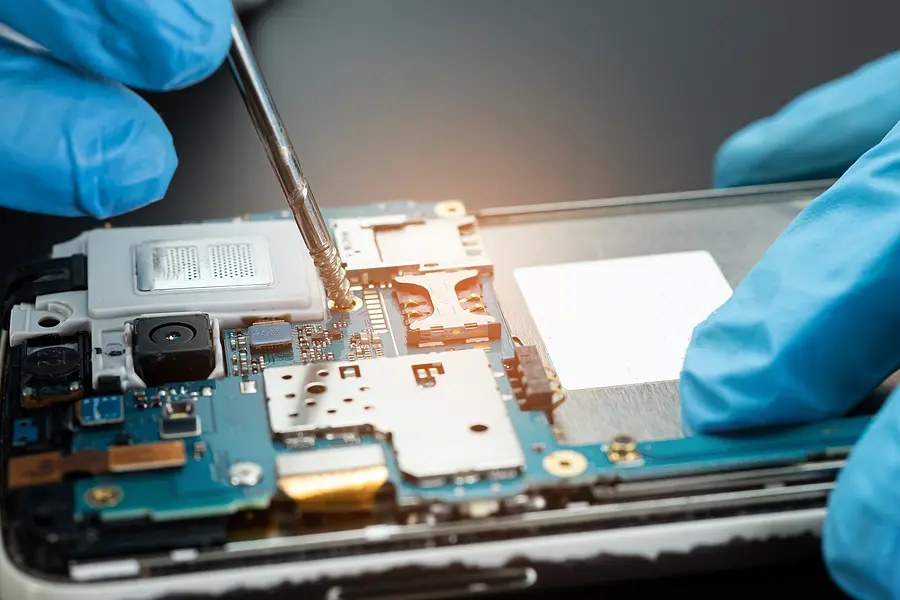

- Performing Quality Inspections-A detailed inspection of the electronic components will often reveal how the part was made. An ECM will know to look for indents, thickness, edging, pins, and texture, which can all help distinguish a legitimate part.

- Thorough Testing-Counterfeit electronic components can slide through when thorough testing isn’t in place. If your ECM is performing thorough testing as part of their process, counterfeit parts will not perform as they should, and will be caught.

- Having a Good Obsolescence Management System in Place-Planning for obsolescence with your distributor will help you avoid the risk of counterfeit parts. A proactive, rather than reactive, plan for obsolescence will ensure that you are not scrambling for parts and being more easily taken in by counterfeit components.

Counterfeit electronic components are a big problem in medical device manufacturing, but one that can be avoided by partnering with the right company to manufacture your medical devices. Working with a company with a good reputation and a thorough process can help assure you that counterfeit electronic components will not put your medical devices at risk. Levison Enterprises is an FDA-registered electronic manufacturer. With years of experience across multiple industries, compliance certifications, including ISO 13485, our vetted supplier network, and on-site engineers, we are the right partner for your next electronic medical device project.