Why Your Electronic Manufacturer Should Use Automated Optical Inspection

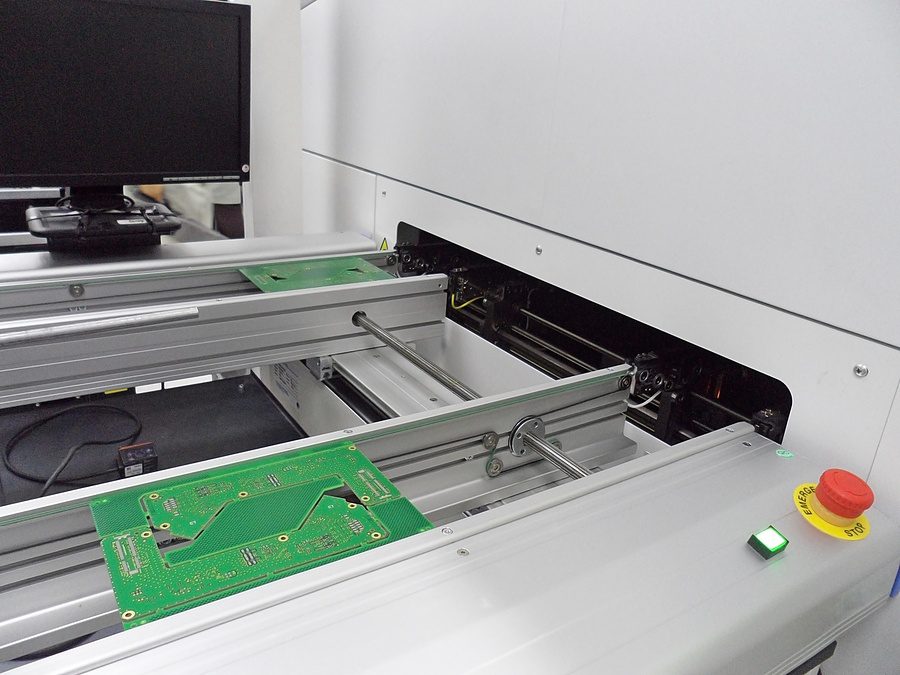

Automated optical inspection or AOI uses an autonomous camera to scan devices for missing components or quality problems. This method of automated visual inspection is a preferred method because it is non-contact and can be implemented throughout the electronic manufacturing process.

Until recently, automated optical inspection was relegated to post-production in order to identify faulty printed circuit boards (PCB) so they could be reworked. Now that automated optical inspection is viable at any stage of PCB fabrication or PCB assembly, it is an even more competitive inspection tool.

The AOI test uses one (or more) high-definition cameras and a variety of lighting sources such as LED, infra-red, ultra-violet and fluorescent. As a circuit board is scanned and photographed, the captured image is compared with the designs that are pre-programmed into the system. This allows the AOI test to immediately detect differences between any board produced and the ideal in the computer system.

Rise of the AOI Test

Nearly all modern electronic devices use a printed circuit board. Simple devices like electronic watches or calculators through complicated aerospace and military machines all require circuit boards to work.

As technologies have advanced rapidly, so have the demands for these types of electronic devices. This results in more complicated and smaller, more condensed circuits. These smaller and more complicated circuits could no longer be manually inspected, primarily because this method cannot detect internal defects. In this more competitive and technical environment, AOI gained popularity because it can provide reliable and quick inspections that can even reduce the cost of production with issues exposed in early phases of manufacture.

Why Use AOI Testing

Many visual inspections that AOI looks for are technically able to be detected by manual visual inspection. Scratches, incorrect or missing components, incorrect soldering, stains, etc. are all things that the human eye can see, but AOI can do it more quickly and accurately.

Additionally, AOI offers benefits that manual visual inspection cannot keep up, let alone with consistent accuracy or quick processing.

Speed

The primary advantage to AOI is speed. It’s really fast. Pre-AOI, a panel of boards could have taken an hour to visually inspect.

Now?

That same panel could take a minute to process. In three to five minutes, AIO includes validation of any errors picked up. The fractional time it takes for an AOI process to detect errors means your product is moving through its entire manufacturing process at a significantly faster clip than visual inspection could have ever provided.

Assuming at least some errors are caught during inspection, these errors are not only detected more quickly, but they can be stopped as soon as they start. As the AOI finds errors they can be fixed before the rest of the job begins production. This equates to more first-pass-yield and much less time reworking.

Accuracy

The accuracy provided by AOI is a very close second to the speed advantage. We often associate rapid speed with decreased accuracy, but this is not the case with AOI. Between the high-speed cameras on AOI machines and a skilled operator, the process detects any tiny defect that might try to slip by. The accuracy of this means more errors can be fixed before the board moves on to its next process.

It may also be assumed that rapid speed and accuracy might mean a sacrifice in consistency. Again, AOI delivers where other processes may have failed. Part of the AOI process involves images that are taken in precisely the same place on every single panel that is run through the machine. These cameras do not miss inspecting a part, here or there, like a human may inadvertently do. And since machines don’t get bored or lose focus, they catch things that the human eye could miss. Not only is the AOI accurate beyond historical visual inspections, it never misses. It’s consistently accurate and fast. What a fantastic combination!

Flexibility

AOI can be placed anywhere in the manufacturing line, based on your product’s needs and your budget. The most efficient and inexpensive places to situate the inspection are where errors are most likely to happen. For circuit boards, this is likely to be right after reflow soldering, but it may be prudent for your product’s test to be elsewhere in the process. Regardless, of where it is placed, the value lies in its ability to go wherever you need it most to dig out potential errors and fix them as they occur and before more product is completed with the error.

Beyond the Benefits

Of course, it sounds nice to have better products more quickly and accurately, but in truth, it’s not just about getting more product done faster. Inspection and testing may very well be the most important step in your product’s entire manufacturing process.

The circuit board in your product is the core component and if it’s not right, the whole product fails. As those circuit boards get smaller and more complex, there is more to inspect and more to potentially go wrong. More potential errors mean the sooner they can be found, the easier and cheaper it is to get them fixed.

This inspection process is the last line of protection you have before your product goes to your consumers. With the rapidly changing technology environment, AOI is no longer just about the benefits, it has become nearly mandatory for electronics manufacturers.

Automated Optical Inspection is one in a range of quality assurance tools at your disposal when Levison Enterprises is your electronic contract manufacturer. If circuit boards are part of your next project, let’s talk about how we can implement the best design, manufacture, assembly, and testing to create a quality and efficient product for you.