An ECM Should Focus on More Than Assembly

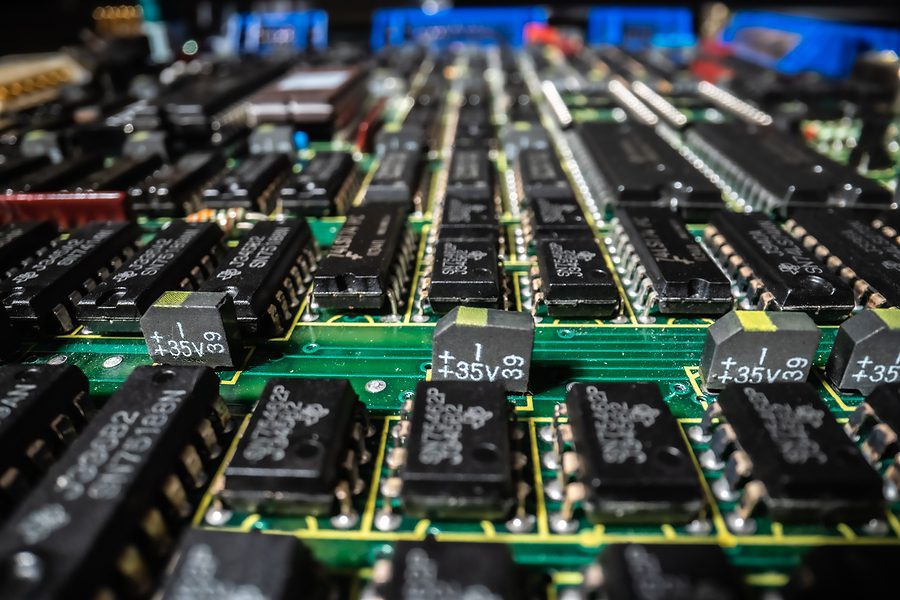

Electronics is one of the largest global industries in the world. Its continued growth has many original equipment providers (OEMs) turning to solution providers that offer industry expertise and experience. This allows them to focus on research and development while a contractor takes over manufacturing.

Electronic Contract Manufacturers (ECMs) provide a wide range of value-added engineering and manufacturing outsourcing services to OEMs. They are a partner that can handle as much or as little of your project as you need them to. But the relationship needs to be more than just someone doing a job they are hired to do. You need an ECM that will anticipate your needs so manufacturing runs smoothly no matter what.

Engineers to Streamline and Troubleshoot

If issues arise during the manufacturing process, your ECM should have a process for handling them. After all, you hired them to make your life easier. Partnering with an ECM with in-house engineers will ensure this happens.

A great ECM has an engineering team ready to step in. They can spot even the smallest detail that may have been overlooked during the design phase and correct it so it doesn’t affect manufacturing. They may also make suggestions that can streamline manufacturing, such as a design tweak or component substitution. Doing this early in the production can save time, money, and resources.

Vetted Supply Chain

Top ECM partners have sophisticated supplier relationships. Suppliers are rigorously vetted upfront and regularly reviewed. The capabilities and quality management systems are thoroughly examined before being used to supply parts for a project.

In addition, your manufacturing partner should have a plan in place to manage parts obsolescence. They should work closely with their suppliers so they know far in advance of any potential parts shortages on the horizon.

Counterfeit Parts Avoidance

The harder a component is to source, the higher the chances of counterfeit parts entering your ECM’s supply inventory. This makes mitigating the risk of counterfeits being used in your build a priority.

Your manufacturing partner needs to have a counterfeit parts avoidance plan in place. This requires strict procedures, inspection tools, and specially trained staff. Counterfeiting continues to become more and more sophisticated, and it’s a common issue in electronic manufacturing. Your ECM must have a plan in place to stay ahead of it.

Transparency

Perhaps the biggest thing to look for in an ECM is a company that is transparent about issues found during manufacturing. You need a partner willing to be accountable.

There should always be an open line of communication between you and your ECM. Questions will come about with even the best-laid plans. If your ECM isn’t asking for clarification, how do you know your design is being followed?

Furthermore, your ECM should communicate issues that arise during manufacturing and share any changes made by engineers.

Conclusion

A worthwhile ECM partnership is one that values everything about your project, is invested in your success, and cares about your end user’s satisfaction. It’s not only about reading your plans and assembling per your requests and specifications. Partnering with an ECM who is transparent and proactive is key.

You need an ECM truly vested in the success of your product and your business partnership. Levison Enterprises is that manufacturing partner. Levison is a full-service design-to-build manufacturer that takes your ideas and turns them into a finished product. We can address any of your manufacturing needs. Our specialty is bringing your concepts to reality. Contact Levison Enterprises today to see how we can assist on your next project.

Start Your Quote Now!