7 Questions to Ask When Choosing the Right ECM for Your Next Project

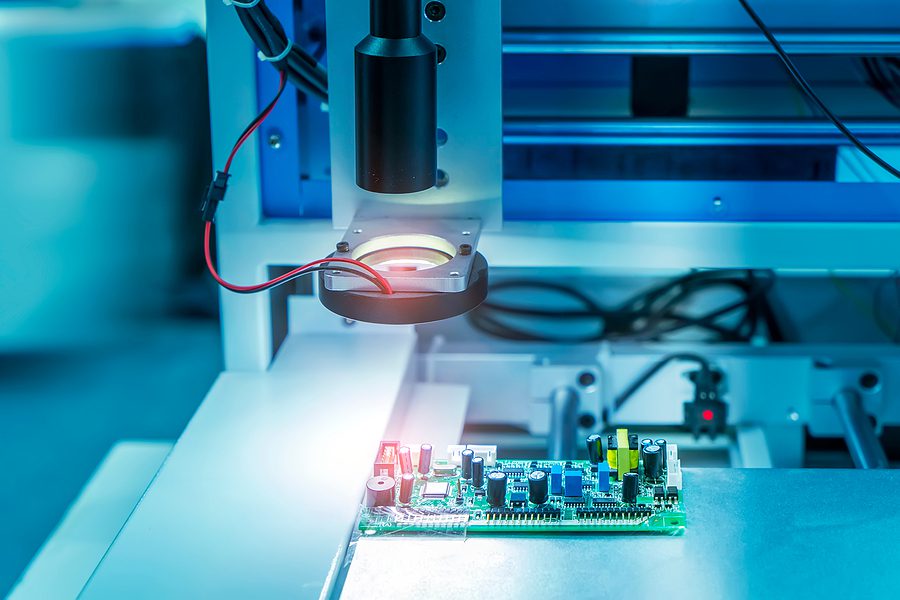

Finding the right electronic contract manufacturer (ECM) to partner with on your next project isn’t always as easy as it sounds. You need someone you can trust to accurately and competitively manufacture your electronic device.

So, how do you know which ECM is right for you?

There are some key factors that need to be looked at to ensure success. Here are seven questions to ask when searching for an ECM for your next project:

1. Do You Have Any Certifications?

The certifications held by an ECM are a clear indicator they work hard and pride themselves on excellence. Compliance indicates you are working with a manufacturer that will protect the integrity of your company and quality of your product.

Certifications to look for include:

- ISO 9001 – The most widely recognized quality certification that demonstrates statutory and regulatory requirements and customer satisfaction.

- AS9100 – An aerospace quality management system considered a “highly stringent” quality standard.

- ITAR (International Traffic in Arms Regulations) – This certification from the United States Department of State controls import and export of sensitive defense-related materials and information.

- IPC and J Standards – These are electronic workmanship certifications for soldering cables and circuit board assemblies

2. Do You Have Engineers On-Site?

Dedicated engineering support is a huge plus when it comes to electronic manufacturing. On-site engineers oversee each stage of the manufacturing process. They will be on hand to detect potential problems and solve them before they snowball and either stall production or leave you with an inferior product.

3. Do You Offer Prototyping?

You need to know how your design functions. And ECM with prototyping services will help with that. Prototyping allows for a small run on your device to test its functionality.

4. How Do You Ensure No Counterfeit Parts Will Be Used in My Build?

Do you want to run the risk of fake or faulty components being used in your electronics? You want an ECM with a solid counterfeit mitigation plan in place. They should have a trusted network of vetted vendors and should do regular parts inspection and testing.

5. Do You Have Experience With My Industry and What I Want to Build?

Experience counts when it comes to a manufacturing partner. You need to be assured your ECM can handle the requirements of your project. Ask about previous clients and projects they previously completed that are similar to yours. Also ask to see samples of their work.

Start Your Quote Now!6. Do You Have a Supply Chain Management Process?

Your ECM needs to do more than just ordering PCB parts and keeping track until they are needed. True supply chain management involves every aspect of tracking a component. They will not only know where they are, but where they have been and what has happened to them in-between.

7. Can You Package and Ship my Finished Product to My Client?

Your ECM knows your product and its specs, so shouldn’t they be able to help choose the best shipping method for your product? Having your completed product packaged and shipped right to your customer is a big bonus. Not only is this convenient, it saves time and gets your product in the hands of your customers faster.

Conclusion

Pay close attention to the answers that you get from your ECM candidates and how they respond to your request. Answers to these questions can help you decide if you have found the right manufacturing partner or if you need to keep looking for someone to make your project a success.

Levison Enterprises knows the right ECM can make all the difference in your product’s quality, cost, and delivery. We are confident we can make your product the best it can be. We pride ourselves on our quality, certifications, and wide range of services – including an in-house team of designers and engineers. Contact us today for a free estimate on your next project and experience the Levison difference.