7 Common Features of a Box Build Assembly in Electronic Manufacturing

Many electronic manufacturers work with multiple vendors on projects. They source components from one company. Another ECM handles sub-assembly. Yet another partner tackles the final assembly. This can waste valuable time and money. Plus, little bits of your quality can fall between the cracks.

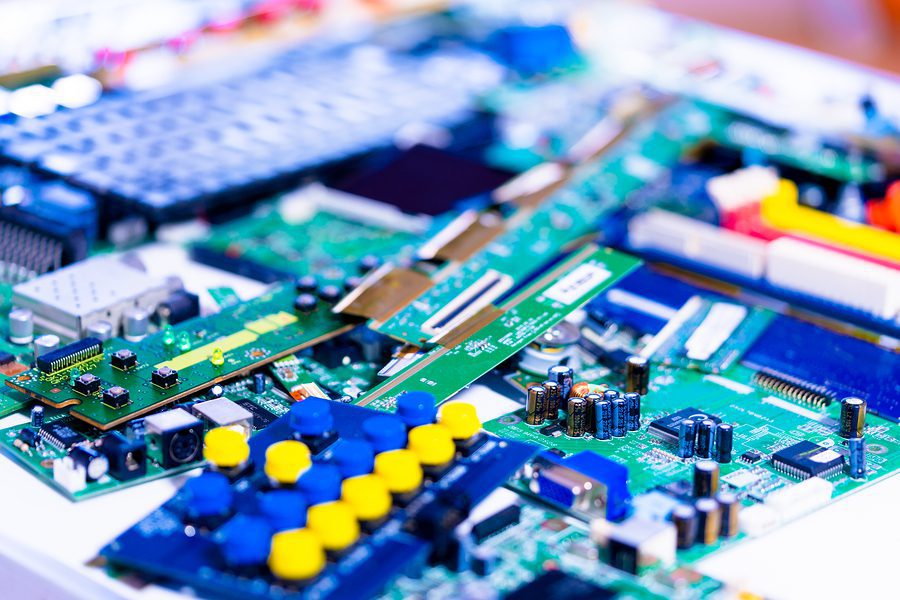

Why send your project to several different sub assemblers? Stick with someone who can be dedicated to your project from start to finish. Find a box build electronics manufacturer and keep it all in one place. A box build is a systems integration. It is your complete electronic assembly placed inside an enclosure, or box. Common services and features of a box build include the following:

1. Design

Perhaps your design needs a little help. Or, maybe you have no idea how to house your electronic assembly. Some electronic contract manufacturers will handle that as part of the box build assembly. Your ECM’s engineers can assist with layout, concepts, material selection, and tooling. Manufacturing is their specialty, so it makes sense to let them handle the design to come up with the perfect solution for your product.

2. Testing

Testing is an important part of product reliability and assures that your product will stand up to everyday use. Your box build assembly should include comprehensive testing and inspection to determine if changes need to be made before assembly begins. This can include prototyping to meet your specifications and helping to detect design flaws.

3. Manufacture Assembly

Your box build team will fully assemble your product from start to finish. They will also help determine the input/output of power, environmental constraints, mounting options, and power sources. They will also take other requirements into consideration, such as high security needs.

4. Sub-Assembly

Several sub-assemblies will go into your finished product. As part of a box build, your ECM will not only design, test, and build the sub-assemblies for your box builds, but they will install them, too.

5. Cable and Wire Harness

High or low voltage cable harness assemblies and wire harnesses will be incorporated into your box build. This can include custom cable assemblies or wire harnesses fabricated to meet your specifications.

6. Custom Enclosure

Sometimes your product needs a special enclosure. It may require unique dimensions or special spacing, routing, or mounting. Your ECM must look at the size and shape of all components, determine how they will stay in place, and take into consideration how the user will access sensors and power.

7. Component Assembly and Installation

Your product may require a special component. Your box build assembler will be able to design and fabricate any special component your electronics assembly will need, as well as install it.

Each box build is unique. It can be as simple as a PCB in a small enclosure to a large cabinet full of wires complete with electronics and pneumatics. Whether your electronic assembly requires a simple, straightforward box build or if you have a complex design, Levison Enterprises has the experience and expertise to meet your needs. Our ISO 9001 and AS9100 certification lets you know our quality control and auditing processes are at the highest standards. Let Levison be your single source for your electronic assembly. Contact us today to see what we can do for your next project.